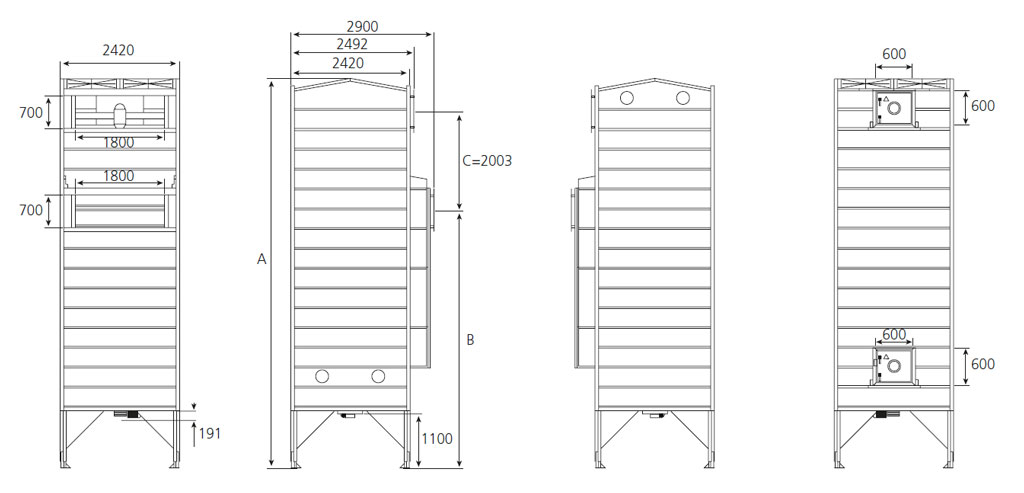

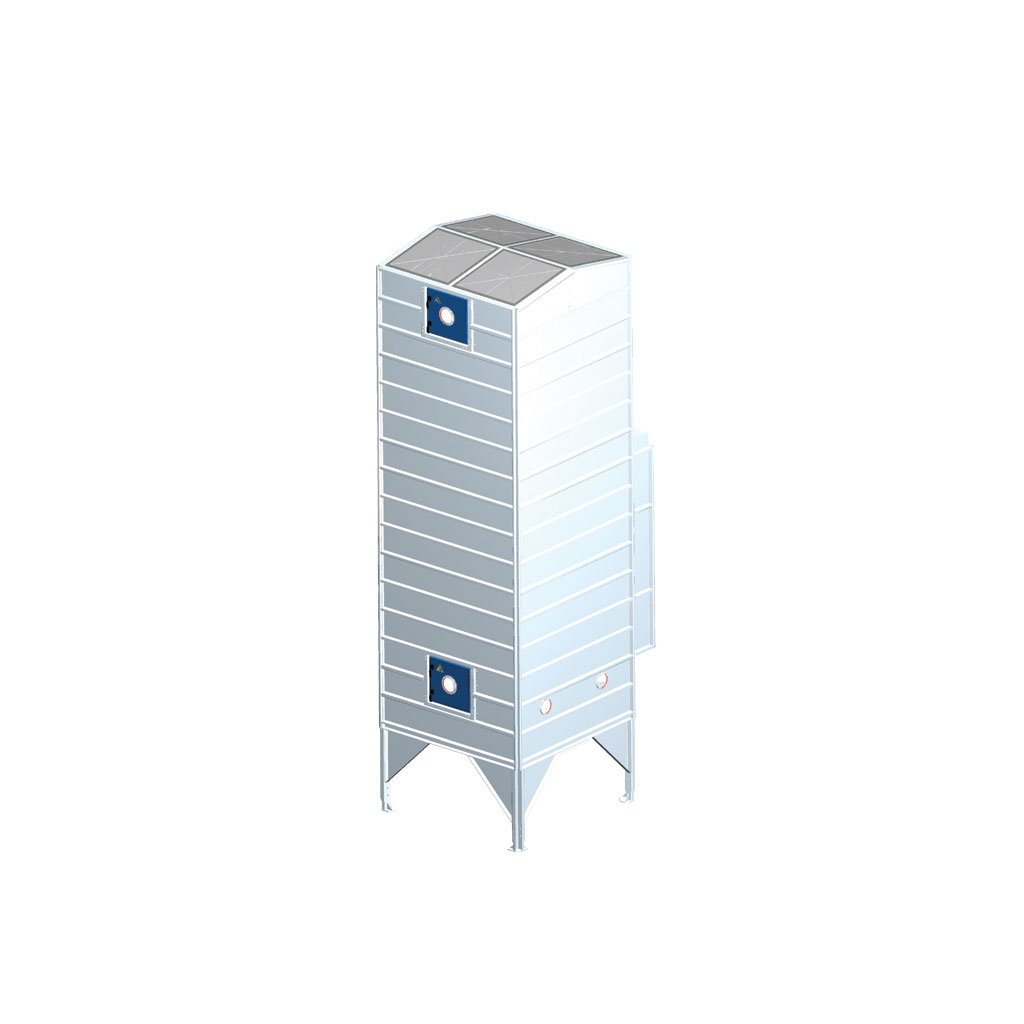

The SuperJet filters are under- and over-pressure filters designed to run in constant operation. The SuperJet filter is made of high tensile steel to ensure strength combined with low weight. The filter is self-supporting with adjustable legs, and can be erected outdoors or in.

Fast assembly

SuperJet filters are factory-assembled as standard with a top part, filter body and bottom part, which can be quickly assembled and erected - or of course supplied separately. It is assembled using bolts in high tension steel with integrated washers, significantly reducing assembly time and the risk of over-tightening bolt assemblies.

Surface

Galvanised sheet, class Z 275 - zinc plating min. 275 g/m² double-sided.

Inlet

The inlet is designed according to the "partial downflow" principle. Contaminated air is passed into the filter and hits a perforated plate which separates most of the dust particles, which settle downwards through the vertical square conduit. The air diffuses through the perforated plate and through the filter bags.

Cleaning system

PowerPulse® cleaning with ECO-PowerPulse® filter control system.

Discharge system

The SuperJet filter is supplied with scraper bottom with discharge to a single B-500 rotary valve, but can be increased to two discharges, B-500 or B-750. Also available with discharge to JK-50S and JK-75S.

ATEX

The SuperJet filter is approved as a zone 20 filter. The filter is fitted with approved explosion membranes. Choose between side venting or JKF’s specially developed VFV® explosion relief venting, which vents explosion pressure vertically through the filter top. The filters fulfil pressure shock-resistance according to VDI 2263. Venting according to VDI 3673.

Operating range

Pressure: +/- 5000 Pa (available up to +10 kPa to -10 kPa)

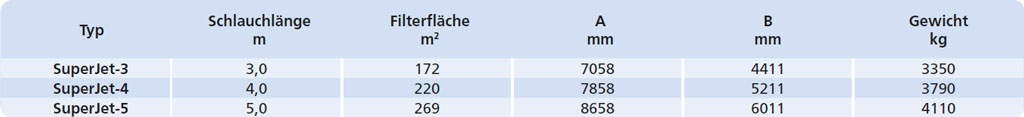

Filter area: 172 - 269 m²

Max. operating temperature: 65ºC

Min. operating temperature: -20ºC (available for -40ºC)

Connection

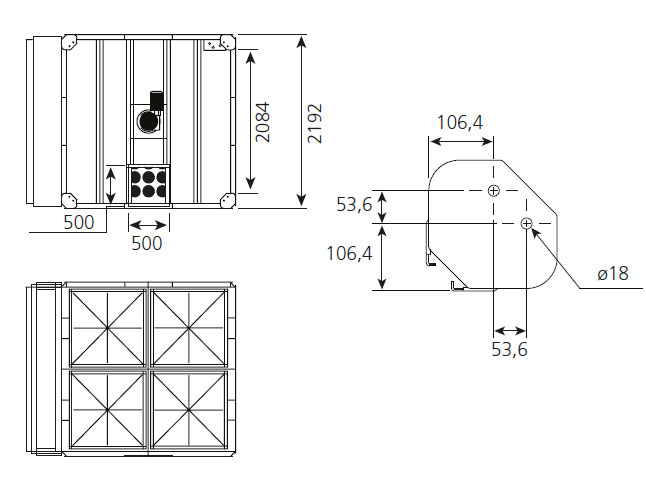

Gear motor scraper bottom:

0,75 kW, 7,8 min-¹, 3x400 V, 50 Hz, 2,7 A

Inductive sensor scraper bottom:

24 VDC

ECO-PowerPulse® filter control system:

0,3 kW, 3×400 V, 50 Hz, 1,1 A (16 A)

External compressed air - PowerPulse®:

6.5 - 8.0 bar, min. 650 Nl/min.

Air quality according to ISO 8573-1: Quality class (5. 4. 4)

External connection: ¼” internal thread.

Noise

Noise level during cleaning measured 5 m above the ground: 69.8 dBA

Ladder/gangway:

Ladder/gangway designed according to ISO/EN/DIN 14122.3/4 and available in several configurations: Ladder with gangway, side-mounted or ladder with double gangway, side-mounted.

Monitoring apparatus for explosion membrane.

Door contacts:

2.3 (close-before-switch-contact) in accordance with EN50047, IP67 NC contact.