Modular filters

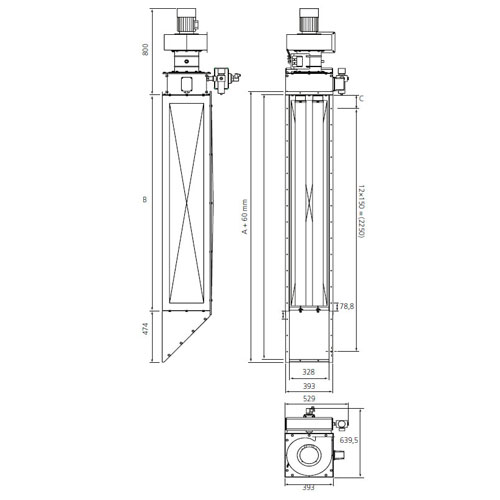

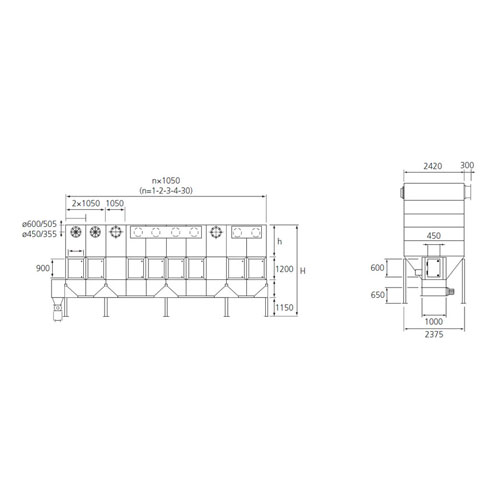

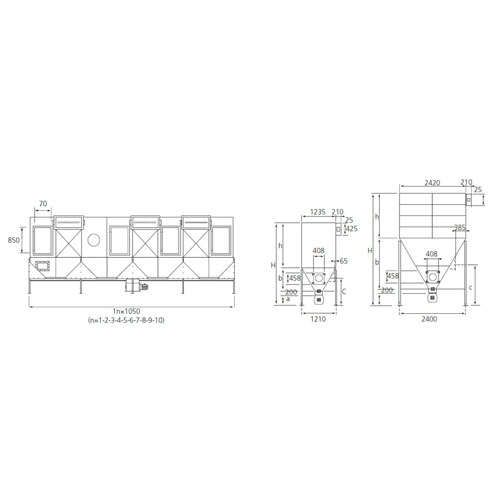

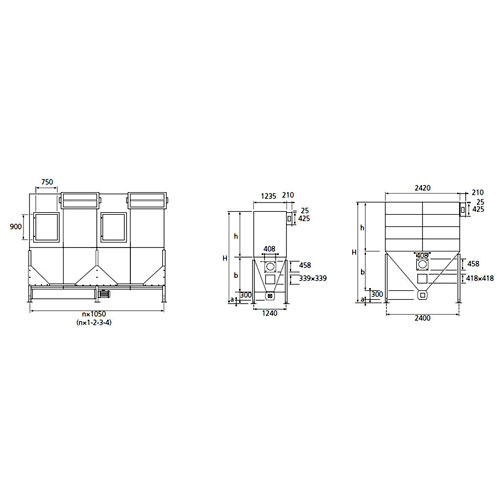

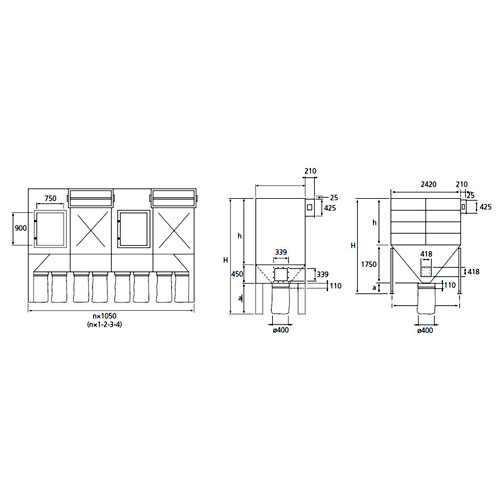

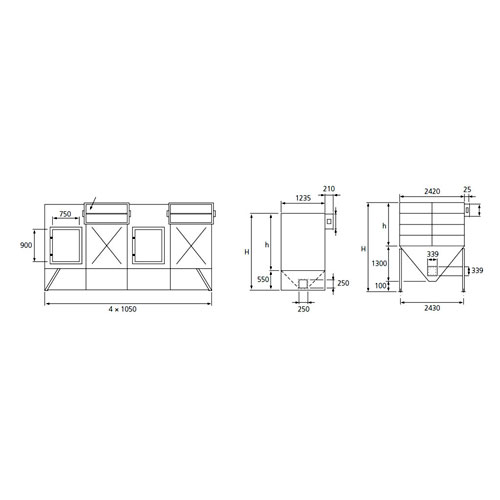

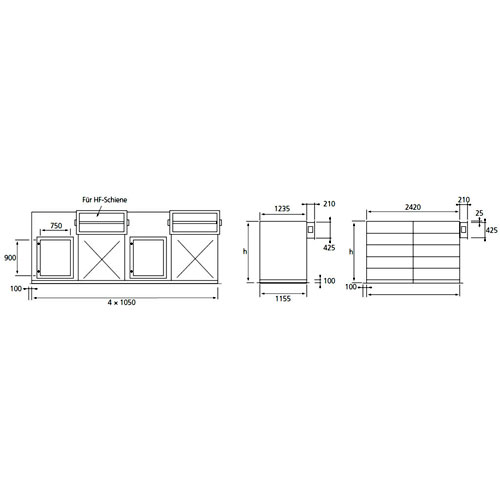

ProTechCon modular dust filters are bag filters. Modular filters can have up to 30 single or double modules, and with various discharge systems: silo, blow through, bag emptying, rotary valve, screw or chain.

They are made of 1.25 and 2 mm galvanised sheet metal.

The standard filter medium is PE40/PE25 bags. The filters are available with different bag lengths, depending on requirements.

The fire damper has a 69°C thermal protection fuse and microswitch connected to the plant's main fan.

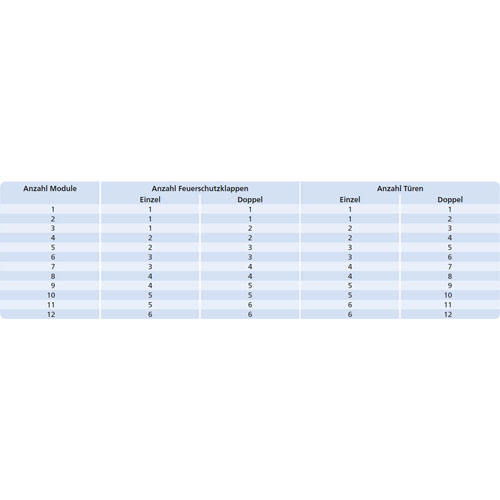

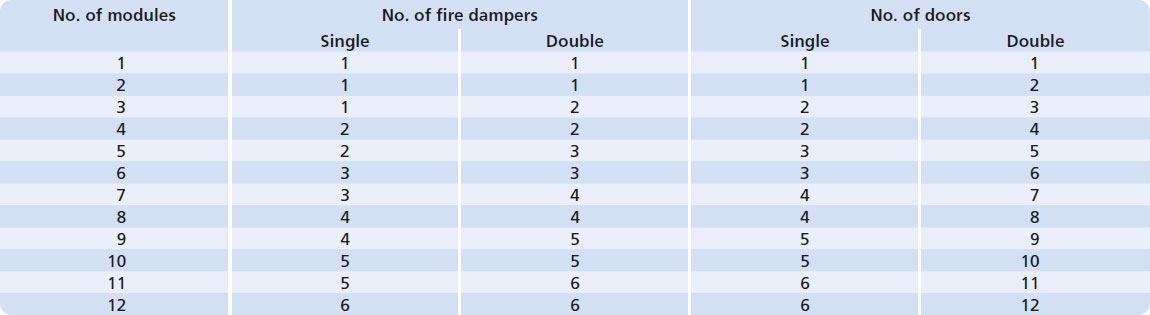

The number of fire dampers and doors depends on the number of modules. See table..

Optional extras

Chain filter type CDF is fitted as standard with a regeneration fan for cleaning filter bags. Other modular filters are available with shaker device or ø450 mm regenerating fan for cleaning the filter bags (ø600 for EX).

Filter height is increased by 150 mm if a shaker device is fitted. The height is increased by 300 mm if a regenerating fan is fitted.

ATEX

Modular filters are not ATEX-approved.

Operating range

Pressure: + 2500 Pa

Filter area: 15.5-1740 m²

Max. operating temperature: 70°C

Min. operating temperature: - 20°C

Connection

Motor:

Regenerating fan

ø450 1.5 kW, 2900 min-1, 3 x 400 V, 50 Hz, 3.2 A

ø600 1.5 kW, 1450 min-1, 3 x 400 V, 50 Hz, 3.2 A

Shaking mechanism

0.75 kW, 121 min-1, 3 x 400 V, 50 Hz, 2.2 A

Screw

0.55 kW, 22 min-1, 3 x 400 V, 50 Hz, 2.5 A

Chain

0.75 kW, 17.5 min-1, 3 x 400 V, 50 Hz, 2.2 A

State number of modules, single or double, filter height/bag length, number of fire dampers and doors, location of supply air and any optional extras when ordering.

If several fans are used for the same filter, a JKF contra-damper must be used on the inlets.