ProTechConcan supply filters for most industry sectors where manufacturing processes generate dust, chips and dirt to be extracted and filtered. Examples:

- Woodworking

- Iron and metal industries

- Surface treatment

- Sandblasting

- Corn, seed and feeds

- Cement and concrete

- Power generation

- Insulation manufacturing

- Packaging manufacturing

- Recycling industries

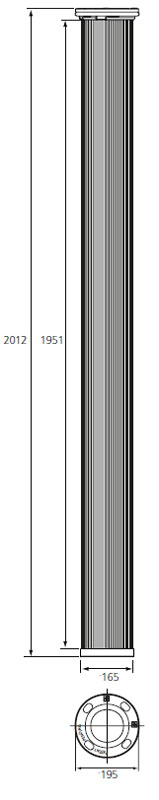

Energy-saving and environment-friendly filter element/pleated filter bag

Filter element consists of polyurethane bottom and top, integral polypropylene support pipe embedded at both ends. The pleated filter medium is on the outside.

The external geometry is largely uniform as are the self-locking fixtures.

The filter elements are available in two basic models with different fold heights in integral support pipes:

1. 16 mm fold height int. support pipe ø127/ø117

2. 24 mm fold height, int. support pipe ø110/ø104

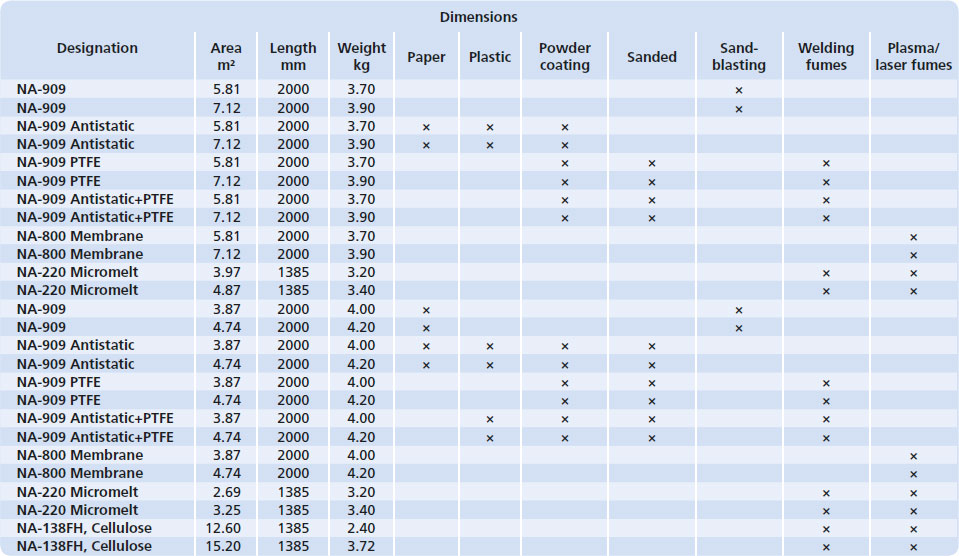

The filter medium is cotton or polyester, which can be coated with a range of finishes:

antistatic, PTFE (Teflon-coated), antistatic and PTFE (Teflon-coated), Teflon membrane.

Polyester can be washed up to 4 times.

The filter elements are also available with - micromelt, which is extremely permeable but with a filtration degree of 99.98%.

Micromelt is non-washable.

- cellulose-coated paper, NA 138 FH, with large surface area. Non-washable.

Pleated bags, offering the following benefits:

- very low pressure loss thanks to optimal geometry.

- 2-3 times more filter area than conventional filter bags.

- self-locking flange makes replacement easy.

- long service life - pleated bags can be washed up to 4 times.

- made of environment-friendly materials.

- used filter elements can be sent for incineration.

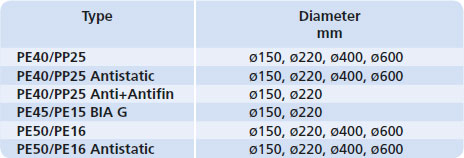

Filter bags

Cotton or polyester filter media with a range of coatings.

Standards: cotton DS-72, polyester PE40/PP25 or PE40/ PP25 antistatic.