The DustStorm® filter is an under- and over-pressure filter, designed for continuous operation.

Constructed as a self-supporting sheet metal construction. The round design ensures great strength combined with low weight.

Surface

Powder coated to corrosion class C3 cf. ISO 12944.

Inlet

Contaminated air passes into the filter through the pressure loss optimised inlet, ensuring optimised separation of the dust particles.

DS-12, 20, 28, 36 and 44 are supplied with side inlet according to the"partial downflow" principle. A diffuser effect which ensures minimum pressure loss with maximum effect. Alternatively, the filters can be fitted with a total separator. DS-7 and 12 are supplied with total separators.

Cleaning system

DS-12, 20, 28, 36, 44 has the PowerPulse® cleaning system with filter control system ECOTROL® or DS total cleaning system. DS-7 EC and DS-12 EC have EC cleaning.

Discharge system

DustStorm® filter is available with conical or scraper bottom. The DS filter is also available as a silo filter. DS-7 is only available with conical bottom.

ATEX

DustStorm® filter is fitted with approved explosion membranes with side relief venting. The filters fulfil pressure shock-resistance according to VDI 2263. Venting according to VDI 3673. The DS filter with external compressed air source is supplied ATEX-approved.

Operating range

Pressure: +/- 5000 Pa (available up to +20 kPa to -10 kPa)

Filter area: 38-534 m²

Max. operating temperature: 70ºC

Min. operating temperature: -20ºC (available down to -40ºC)

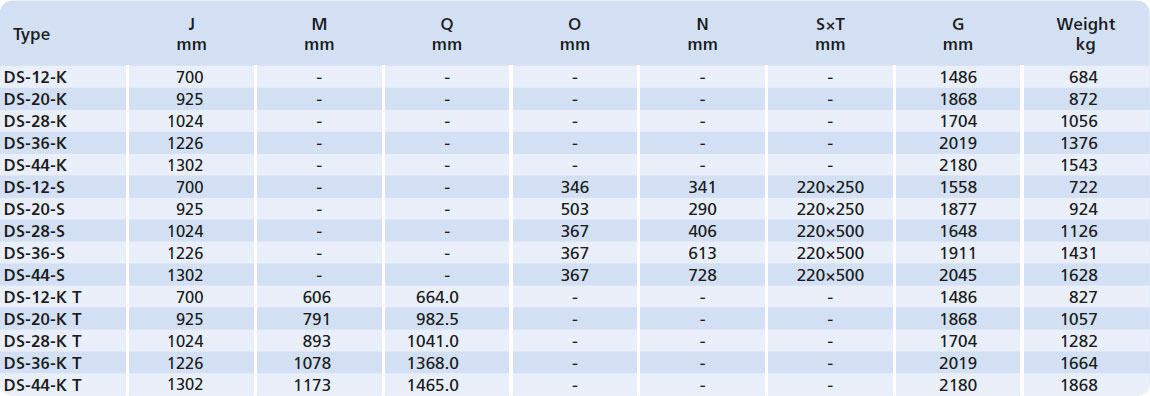

Connection DS-12 – DS-44

Gear motor PowerPulse® cleaning system:

0,12 kW, 15,6 min-¹, 3 x 230 V, 50 Hz, 0,7 A

Gear motor scraper bottom:

DS-12-S: 0.25 kW, 15.7 min-¹, 3 x 400 V, 50 Hz, 1.1 A

DS-20-S and DS-28-S: 0.37 kW, 15.7 min-¹, 3 x 400 V, 50 Hz, 1.6 A

DS-36-S and DS-44-S: 0.75 kW, 11.0 min-¹, 3 x 400 V, 50 Hz, 2.2 A

Inductive sensor scraper bottom:

24 VDC.

-

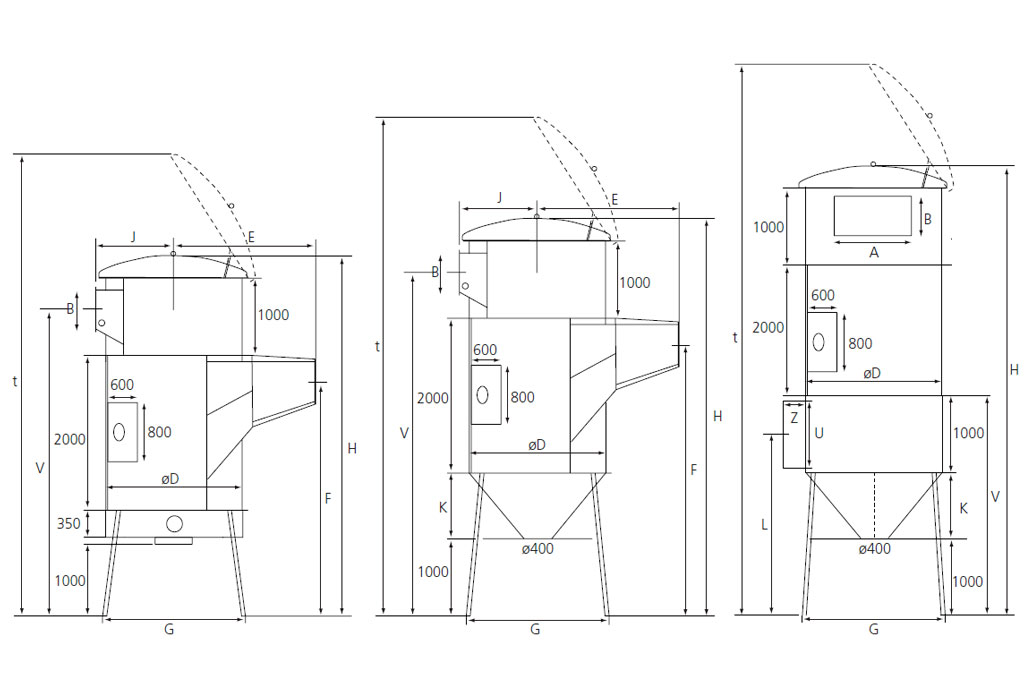

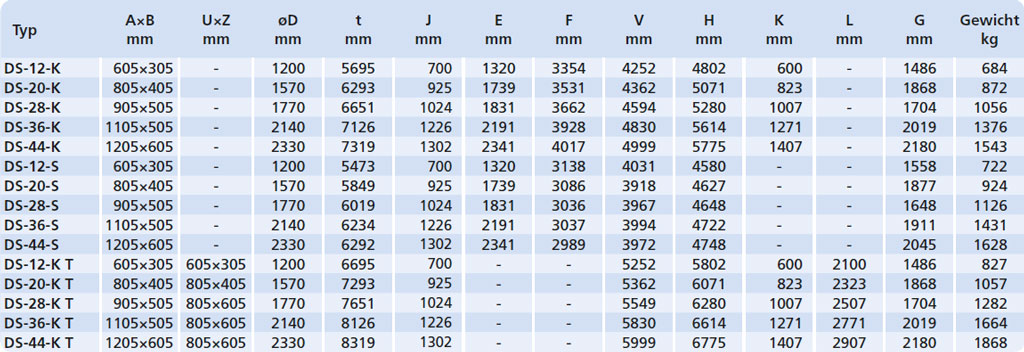

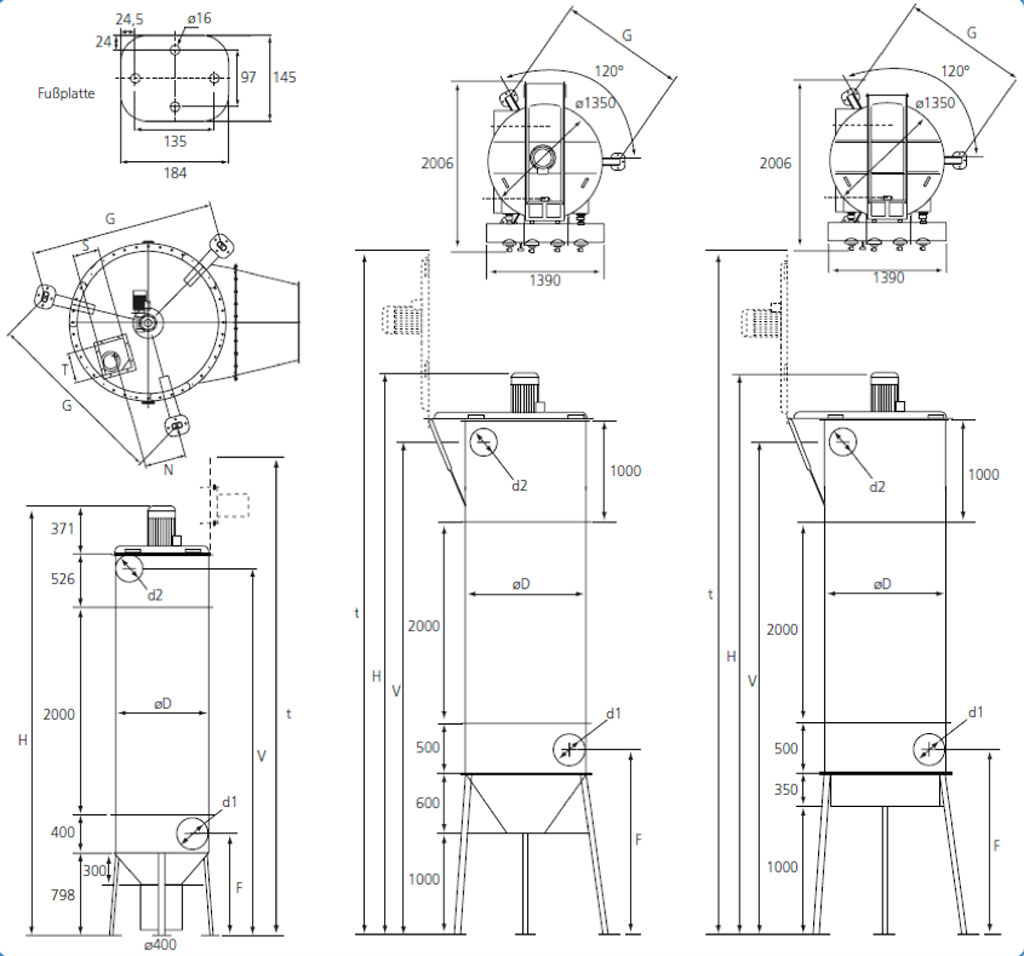

DustStorm®-filter with conical bottom and bucket. Fitted with ladder and platform.

DustStorm®-filter with conical bottom and bucket. Fitted with ladder and platform. -

DustStorm® filter with scraper bottom.

DustStorm® filter with scraper bottom. -

PowerPulse® ECOTROL® filter control system:

0,6 kW, 1 x 230 V, 50 Hz, 1,9 A

PowerPulse® DS total filter control system:

0,7 kW, 1 x 230 V, 50 Hz, 2,1 A

External compressed air - PowerPulse®:

DS-36 and DS-44 (for cleaning system and roof opening):

7.5 bar, min. 350 Nl/min.

DS-12 and DS-28 (for cleaning system):

5.0 bar, min. 350 Nl/min.

Air quality according to ISO 8573-1: Quality class (5. 4. 4)

External connection: ¼” internal thread.

Internal compressor - PowerPulse®:

2,2 kW, 3 x 400 V, 50 Hz, 5,9 A

Capacity: 350 Nl/min.

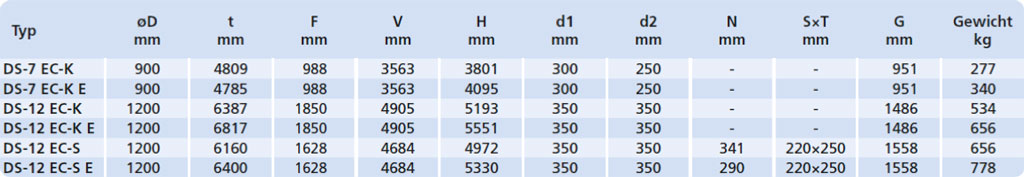

Connection DS-7 EC and DS-12 EC

EC filter control system:

0,2 kW, 1 x 230 V, 50 Hz, 0,8 A

External compressed air – EC cleaning system:

5 bar, min. 400 Nl/min.

Air quality according to ISO 8573-1: Quality class (5. 4. 4)

External connection: ¼” internal thread.

Integrated fan:

DS-7 E EC: 4,0 kW, 3 x 400 V, 50 Hz, 11,0 A (JK-30MTD)

DS-12 E EC: 11,0 kW, 3 x 400 V, 50 Hz, 19,0 A (JK-40MTD)

Accessories

Ladder/gangway:

Ladder/gangway designed according to ISO/EN/DIN 14122.3/4 and available in several configurations.

Monitoring apparatus for explosion membrane.

Door contacts:

2.3 (close-before-switch-contact) in accordance with EN50047, IP67 NC contact.

Noise

Noise level during cleaning measured at 5 m above ground.

DS-7 EC and DS-12 EC: 70.0 dBA

DS-7 EC E: 71.0 dBA

DS-12 EC E: 75.4 dBA

DS-12 ET EX - DS-44 ET EX: 70.0 dBA

DS-12 ET - DS-44 ET: 72.4 dBA

-

DS-EC-K E R

DS-EC-K E R -

-

DS-EC-S E R

DS-EC-S E R

DustStorm®-Filter with PowerPulse® cleaningsystem

DustStorm® filter with EC cleaning system

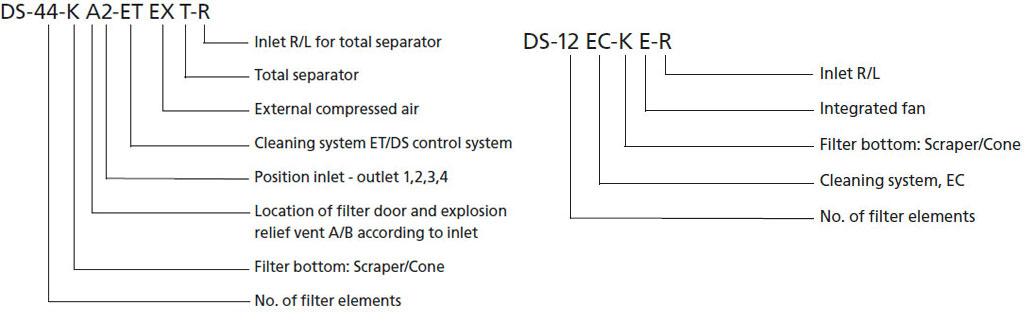

Type designations

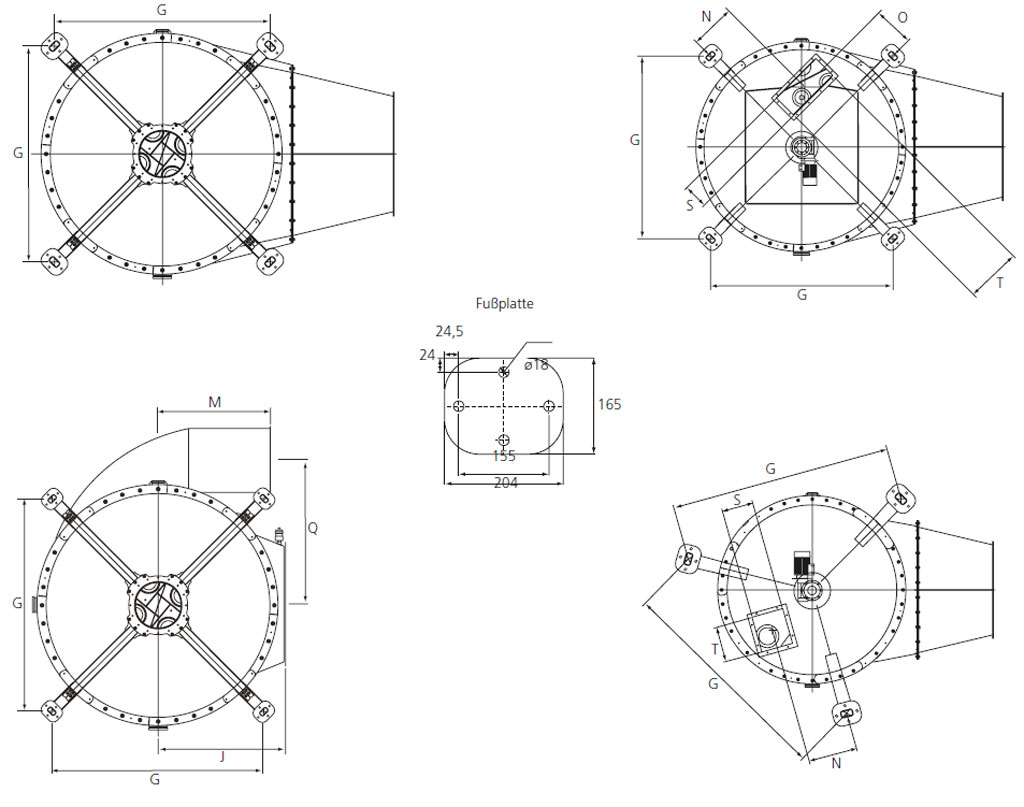

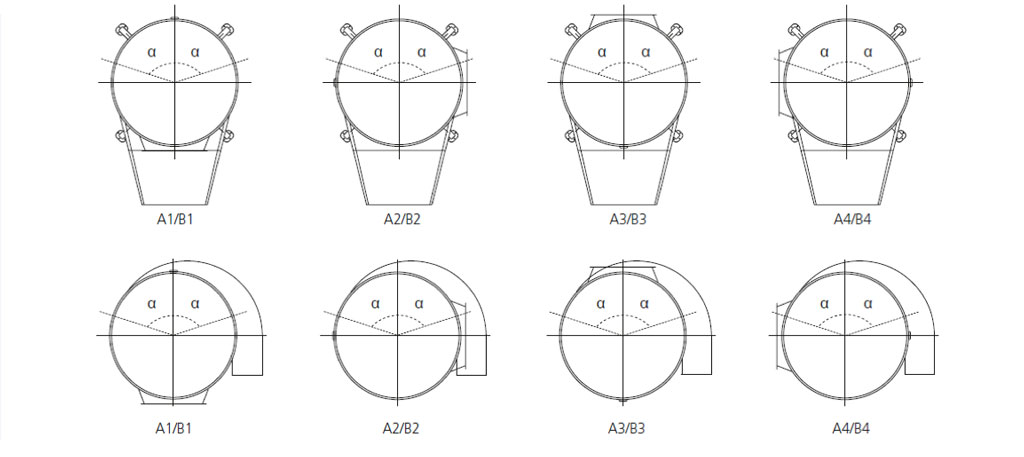

Filters are type-designated using a combination of letters and numbers separated by hyphens and spaces. Designation DS-44-K A2-ET EX T-R thus describes a DustStorm® filter with 44 filter elements, conical bottom, filter door on the left side, outlet to the right, cleaning system ET, external compressed air, right inlet for total separator.

A: Filter door located on left side and explosion relief venting on right in relation to inlet.

B: Explosion relief venting located on left side and filter door on right in relation to inlet.

Roof hinging:

DS-36 and DS-44: Hinged opposite outlet.

DS-12 and DS-28: Hinge on right/left 90SDgr in relation to outlet.