Magnetic roller separator/MAGNETIC COOLATING- FILTER for cooling oils and emulsions

Magnetic rolller for cooling fluids and oils is used for separation of ferromagnetic particles from cooling fluids and oils in machine tools.

“DLR” magnetic separators are used in the treatment of liquids which contain ferrous parts and for the cleaning of integral cutting oils.

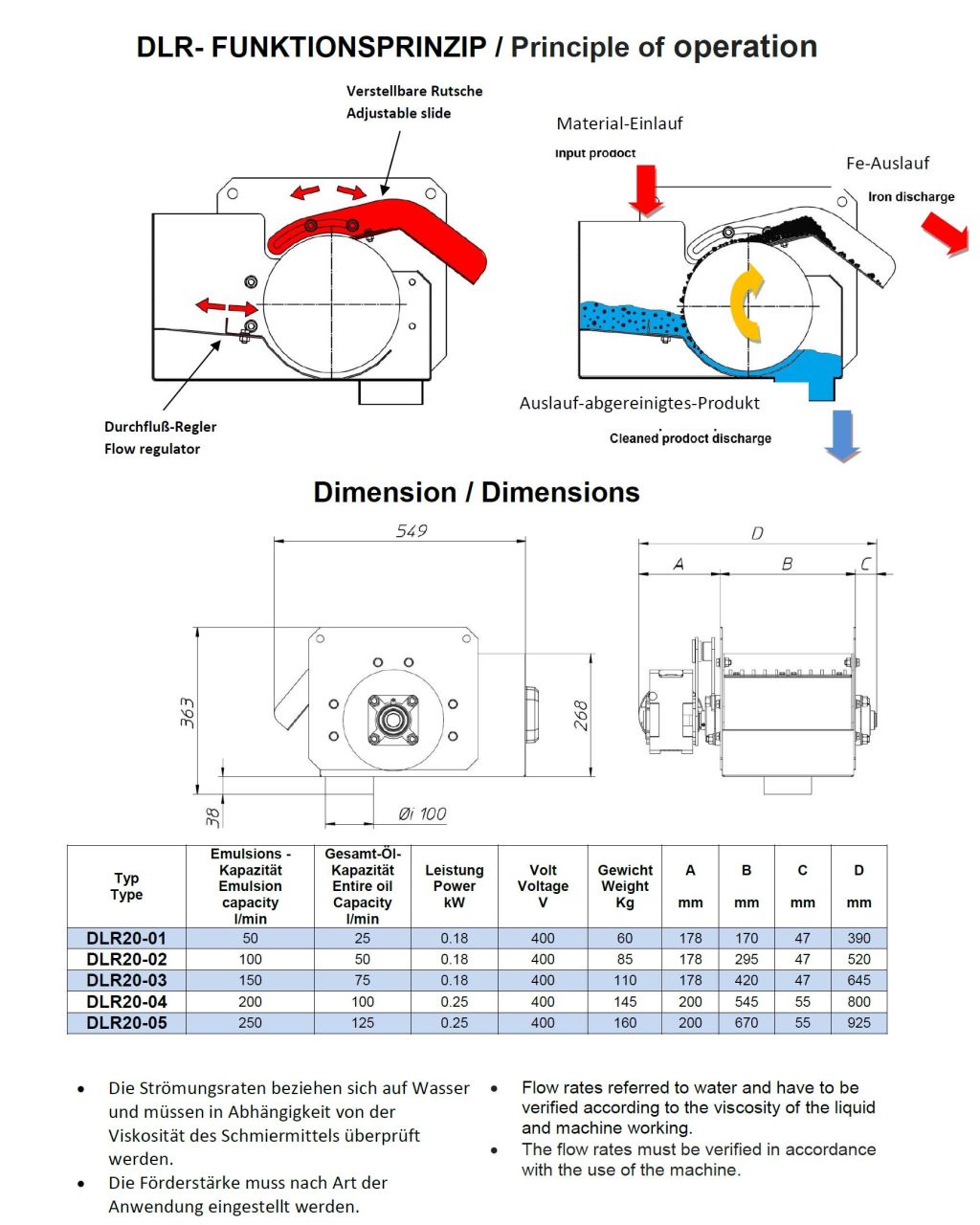

The Fe-separation takes place through a radial polarity magnetic roller immersed inside the product which attracts the ferrous particles present in it.

The ferrous particles are removed from the system by a scraper connected to a chute, the slope of which is designed to ensure maximum discharge efficiency. The simple construction and the choice of materials make the magnetic separator "DLR" maintenance-free.

The magnetic iron remover "DLR" consist of:

- Structure entirely made of stainless steel AISI 304.

- Magnetic roller equipped with ferrite magnets and composed by nucleuses in soft iron and low carbon content.

- Geared motor mounted outside the structure.

- Internal flow regulator optimizes the separation according to the flow of the product.

- Adjustable slide allows changing the angle of discharge. It allows better compression of the iron extracted and consequently a lower loss of

APPLICATIONS:

grinding; centers and hardening lines etc.

Automatic roller separator DLR