The SuperBlower filter is an under- and over-pressure filter designed to run in constant operation.

Constructed as a self-supporting sheet metal construction in high tensile steel modules. Process air is passed into a filter chamber, where the larger particles settle to the bottom of the filter, from where the air is passed through filter bags which retain the residual particles.

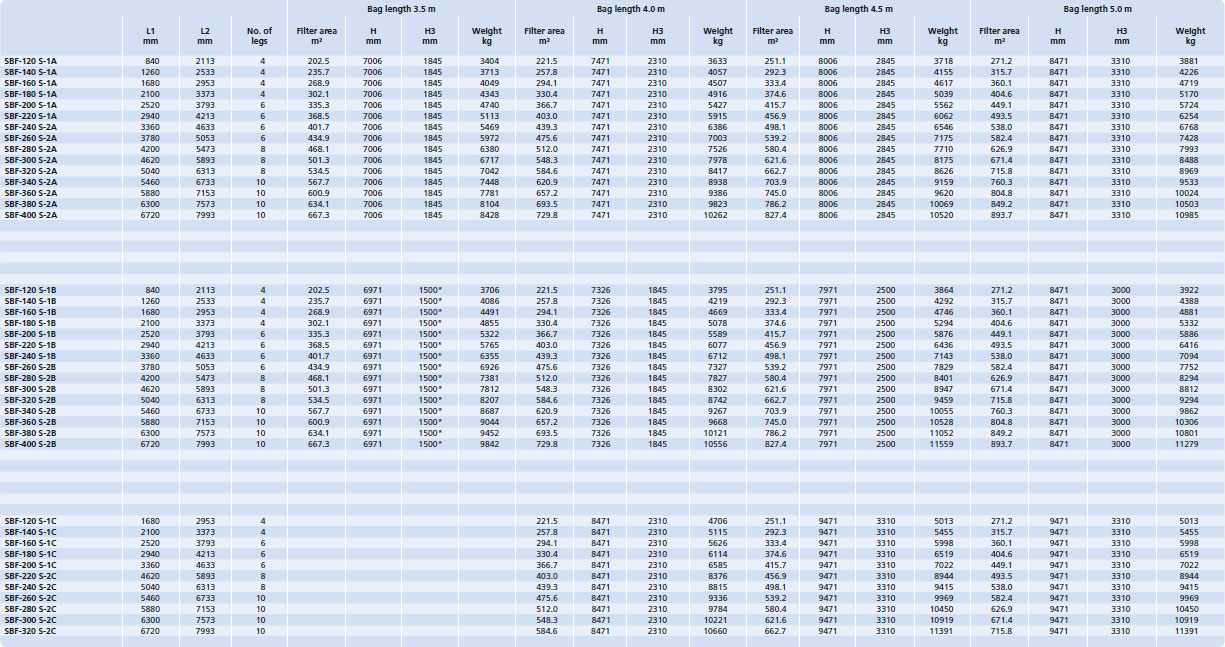

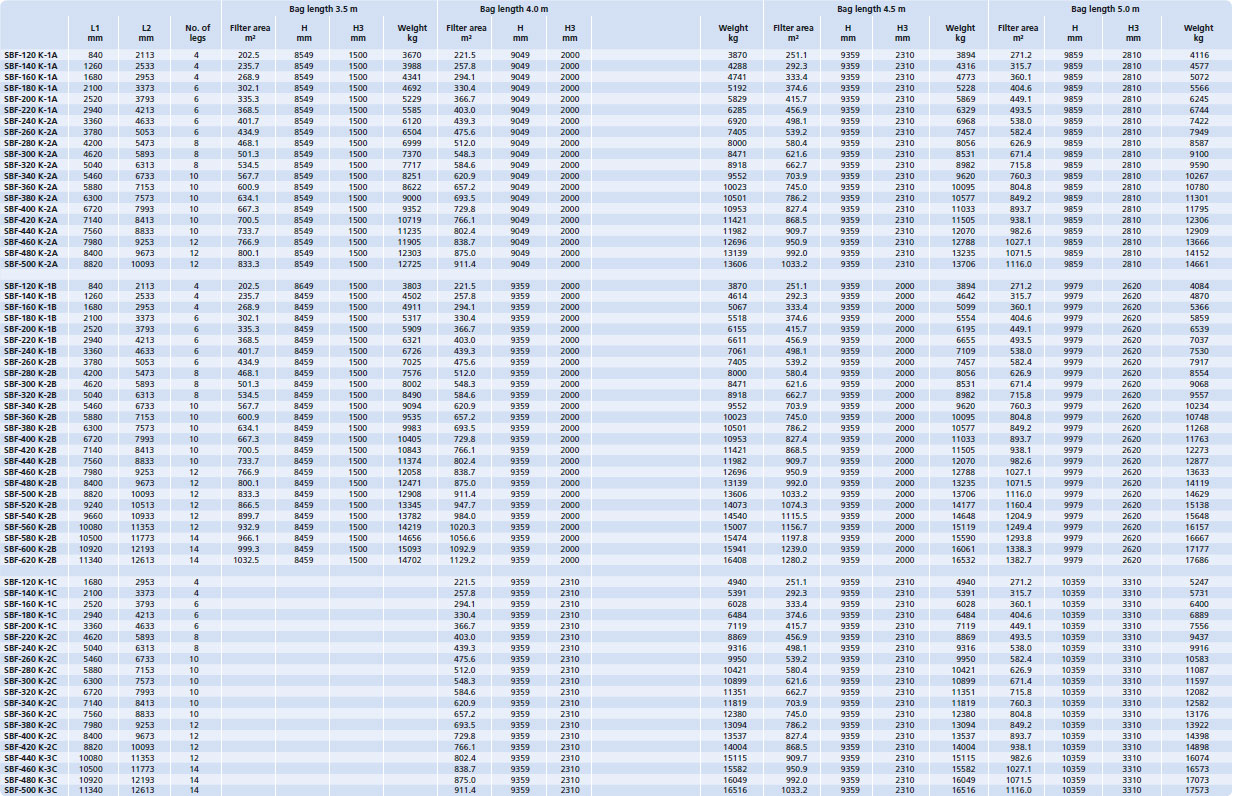

The modular SuperBlower filter is a flexible design which can be adapted to any given task in terms of capacity and function. In terms of capacity, dimensioning of filter height and the number of filter bags; in terms of function, the choice between different types of inlet, cleaning systems and discharge systems.

Surface

Powder coated to corrosion class C3 cf. ISO 12944.

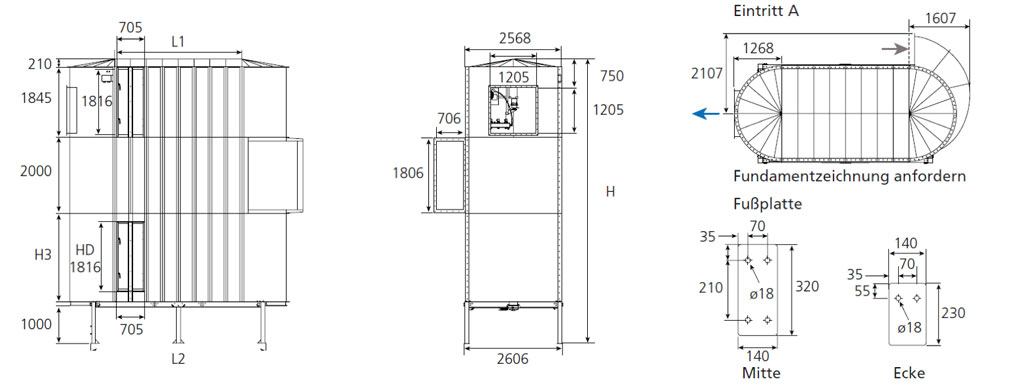

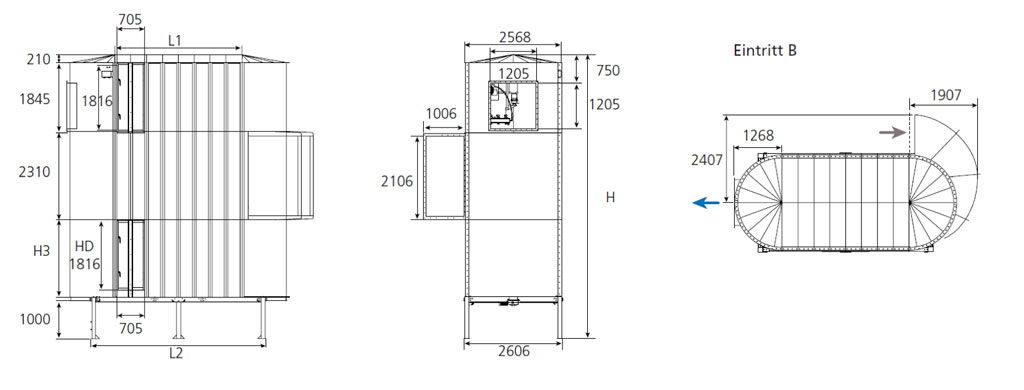

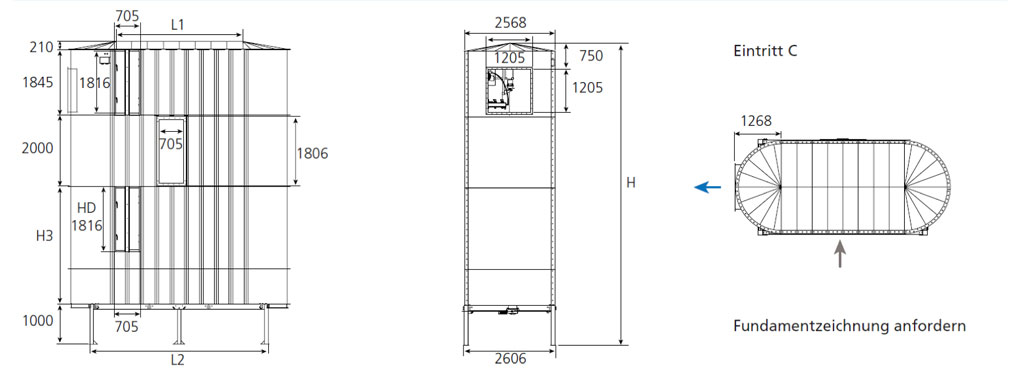

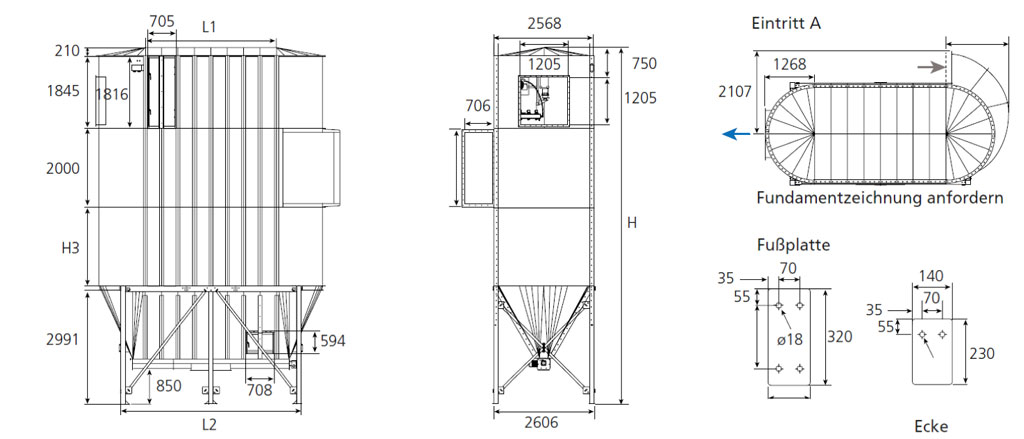

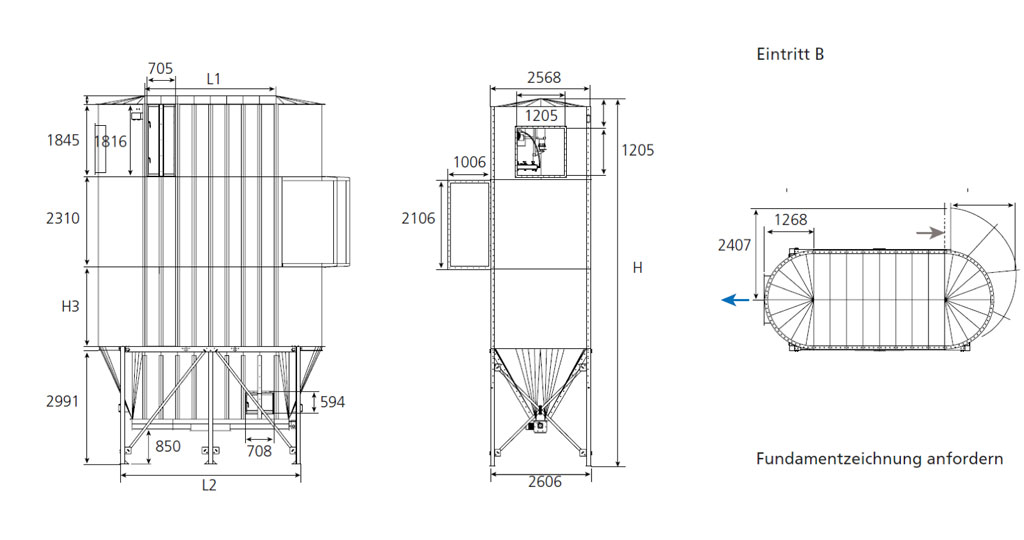

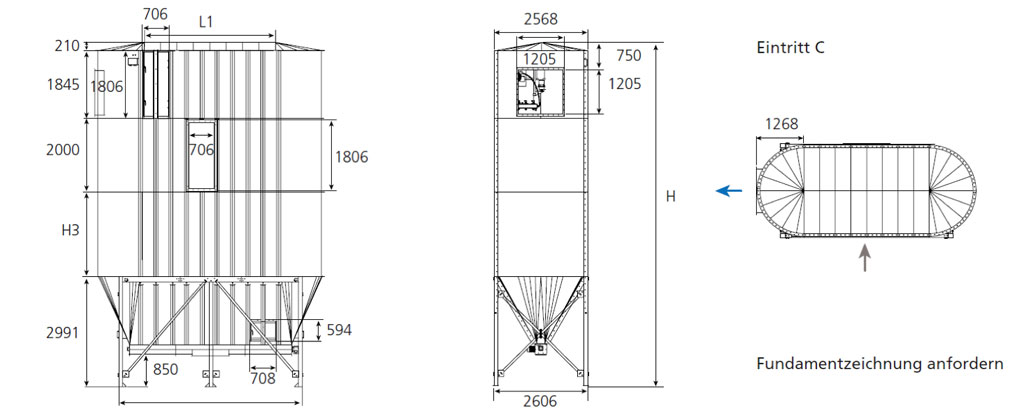

Inlet

The SuperBlower filter is available with 180º tangential inlet, standard 706 x 1806 mm or large 1006 x 2106 mm. Inlets can be fitted at both ends of the filter. Alternatively, one or more Coanda side inlets can be supplied.

Cleaning system

Two different cleaning systems are available: HPBS cleaning or Power-Pulse®.

Discharge system

Conical bottom with screw and rotary valve or scraper bottom with rotary valve or bucket/container.

ATEX

SuperBlower filter with PowerPulse® cleaning and external compressed air is ATEX approved and fitted with approved explosion membranes. Choose between side venting or JKF’s specially developed VFV® explosion relief venting (vertical explosion relief venting through the filter top). Fulfils pressure shock-resistance according to VDI 2263. Venting according to VDI 3673.

Operating range

Pressure: +/- 5000 Pa (available up to +20 kPa / -10 kPa)

Filter area: 203-1383 m²

Max. operating temperature: 70ºC

Min. operating temperature: -20ºC (available down to -40ºC)

Connection

HPBS side channel blower:

7,5 kW, 3 x 400 V, 50 Hz, 15 A

HPBS filter control system:

0,5 kW, 1 x 230 V, 50 Hz, 1,8 A

Gear motor cleaning carriage:

0,18 kW, 20,0 min-1, 3 x 230 V, 50 Hz, 0,9 A

Gear motor scraper bottom:

2 x 0,75 kW, 17,5 min-1, 3 x 400 V, 50 Hz, 2 x 2,2 A

Inductive sensor, scraper bottom:

24 VDC

Screw:

SBF-120 – SBF-380

0,75 kW, 43,0 min-1, 3 x 400 V, 50 Hz, 2,2 A

SBF 400 – SBF 640

2 x 0,75 kW, 43,0 min-1, 3 x 400 V, 50 Hz, 2 x 2,2 A

Shown here with VFV® explosion relief venting in filter top.

Shown here with VFV® explosion relief venting in filter top.

PowerPulse® filter control system:

0,6 kW, 1 x 230 V, 50 Hz, 1,9 A

External compressed air - PowerPulse®:

5 bar, min. 350 Nl/min.

Druckluftqualität gemäß ISO 8573-1: Qualitätsklasse (5. 4. 4.)

Äußerer Anschluss: ¼” Innengewinde.

Internal compressor - PowerPulse®:

2,2 kW, 3 x 400 V, 50 Hz, 5,9 A

Kapazität: 350 Nl/min.

Noise

Noise level during cleaning measured 5 m above the ground:

Externe Druckluft PowerPulse®: 69,8 dBA

Interner Kompressor PowerPulse®: 74,6 dBA

HPBS: 76,5 dBA

Accessories

Ladder/gangway:

Ladder/gangway designed according to ISO/EN/DIN 14122.3/4 and available in several configurations.

Ladder with gangway, front-mounted

Ladder with gangway, side-mounted

Ladder with gangway, front-mounted

Ladder with double gangway, side-mounted

Monitoring apparatus for explosion membrane

Door contacts:

2.3 (close-before-switch-contact) in accordance with EN50047, IP67 NC contact.

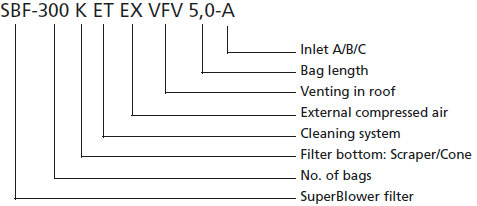

Type designations

Filters are type-designated using a combination of letters and numbers separated by hyphens and spaces.

Designation SBF-300 K 5.0-2C thus describes a SuperBlower filter with 300 filter bags, conical bottom, 5 m filter bags and 2 side inlets.

Shown here with VFV® explosion relief venting in filter top.

With ladder and platform mounted.

Cross-section shows Coanda plates, used to accelerate and compress

particles so that they settle to the bottom.