Duct Systems

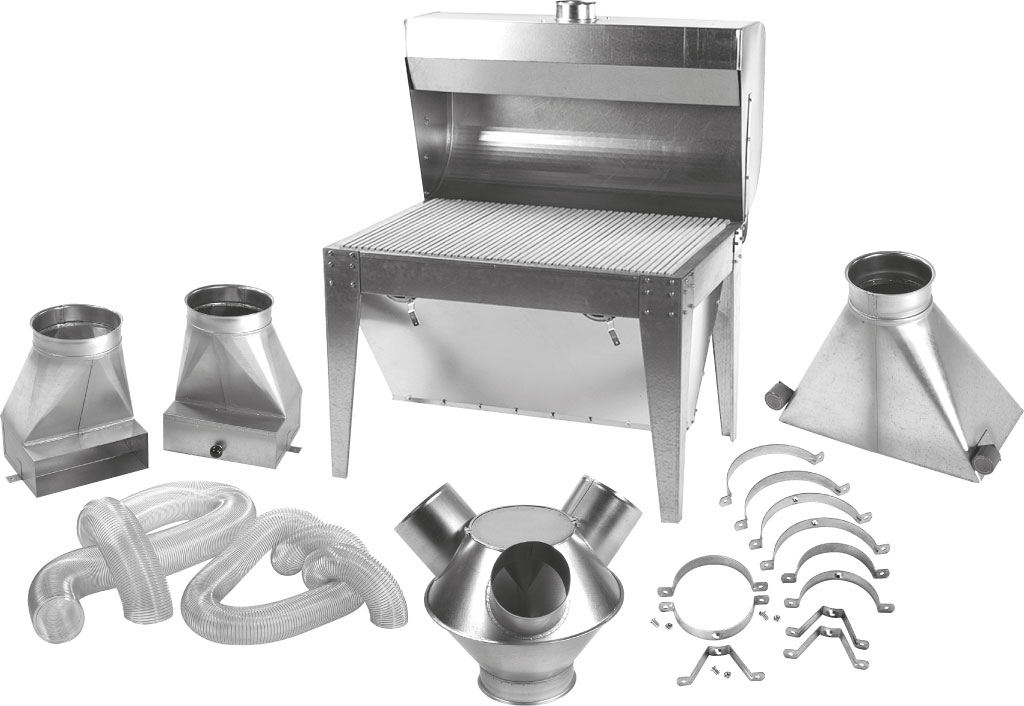

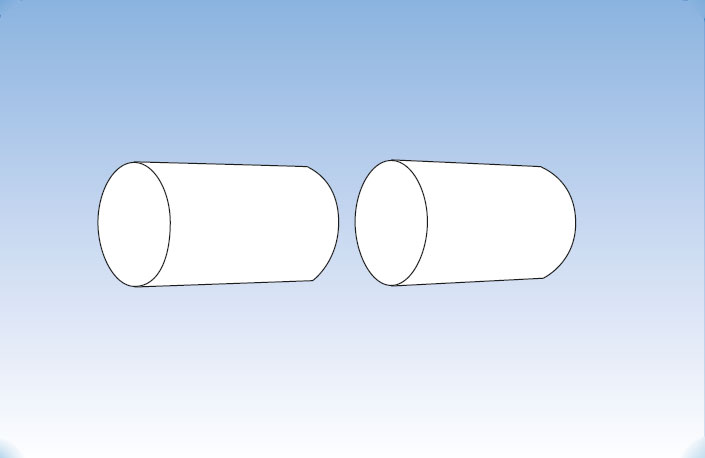

PTC programme includes galvanised duct systems and welded duct systems in 2 and 3 mm material thickness, and thus represent the basic element in extraction and transport of particles and air.

PTC duct systems have a circular cross section, with a wide range of ducts, bends, trouser-, branch-, end-, transition and taper pieces, throttle valves, diverters, jet- and rain caps etc. to ensure individual adaptation and a high degree of flexibility.

This catalogue covers JKF’s standard components for the following dimensions: ø80 – ø1000 mm.

Special customised components are available to order.

Galvanised duct system

The galvanised duct system includes all components necessary for a complete and flexible extraction solution and can be used for particle transport, welding extraction etc.

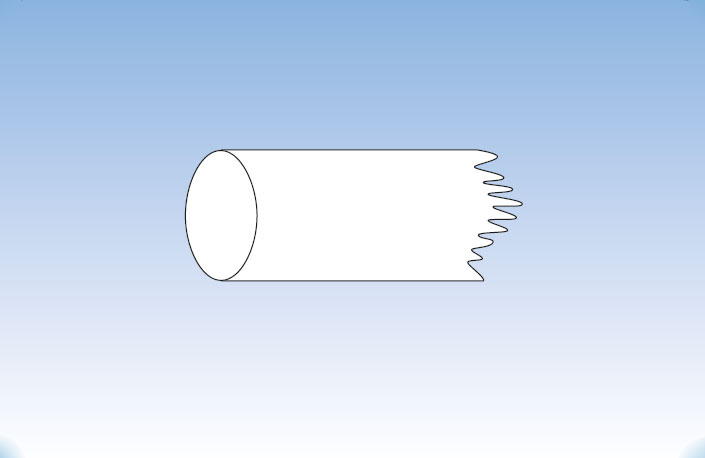

- laser welded ducts

- longitudinally lock formed ducts

- pressed bends

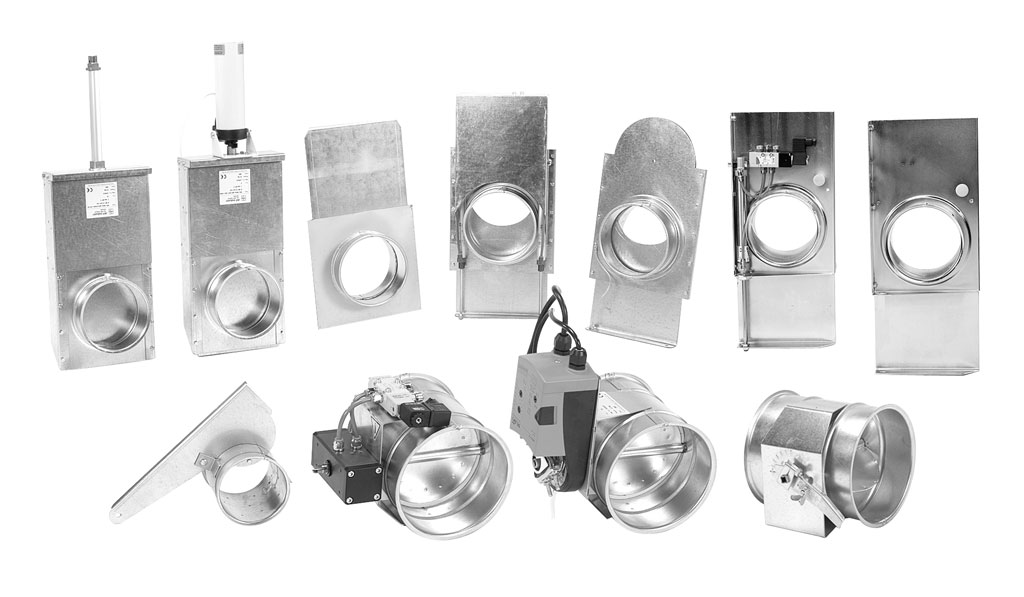

- tight sliding dampers

- branch- and trouser pieces

- throttle valves

- adapters

ø80 - ø400 mm ducts are laser welded. Other sizes are longitudinally lock formed ducts.

Bends, branch pieces, shaped pieces etc are assembled with overlap and point-welded.

Ducts and shaped pieces are manufactured from hot dip galvanised steel sheet: Dogal 280, DX 51 D, DX 54 D or DX 56 D with material thickness from 0.75 mm – 1.25 mm.

Surface treatment class is Z 275 - i.e. zinc coating is minimum 275 g/m2 double sided.

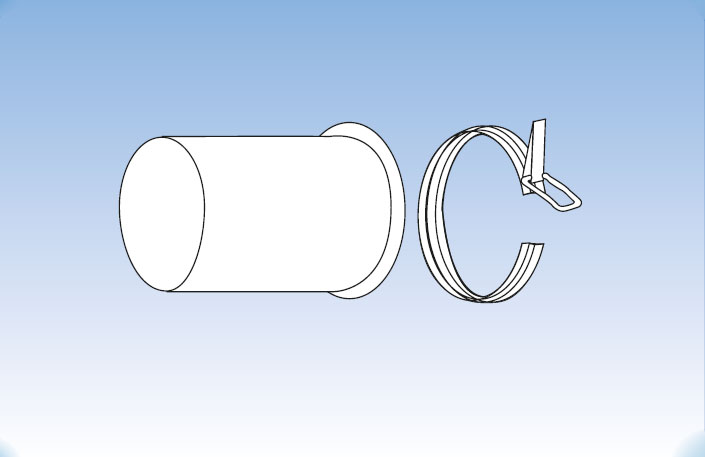

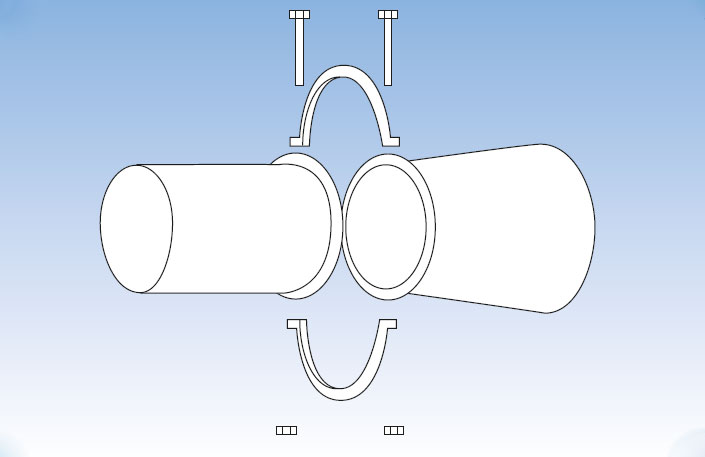

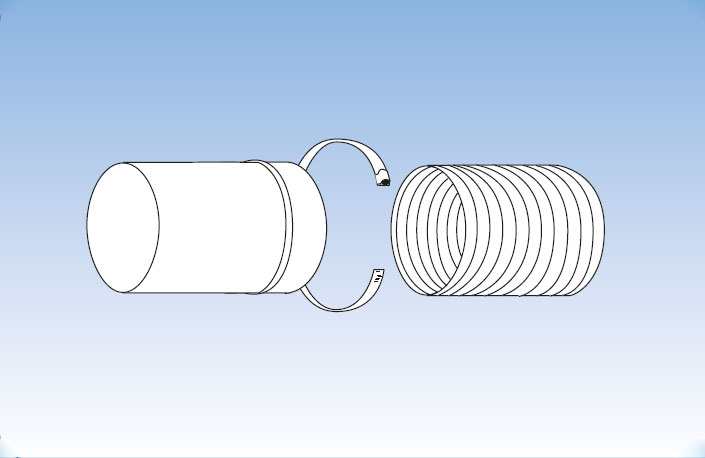

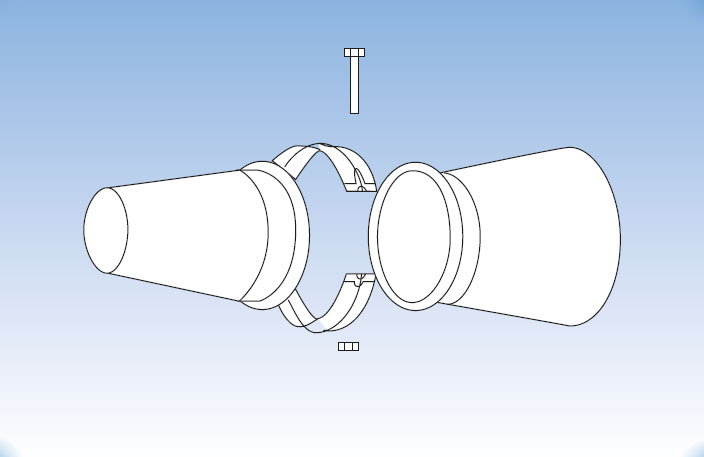

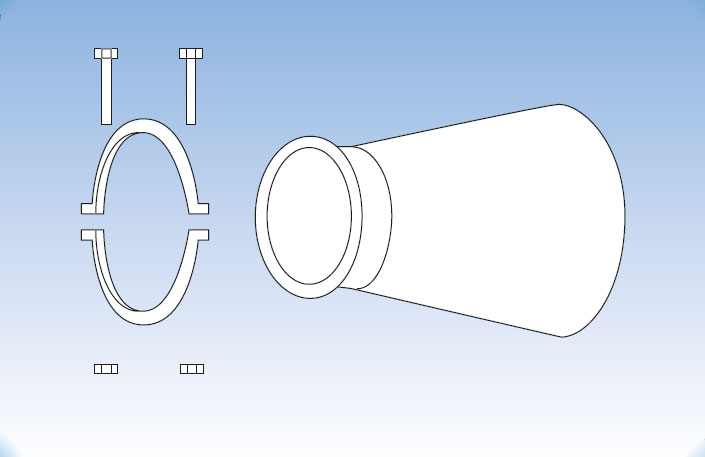

Pull rings [f.b] are used as standard joint assembly for rapid assembly and separation on ø80 mm to ø800 mm ducts, and loose

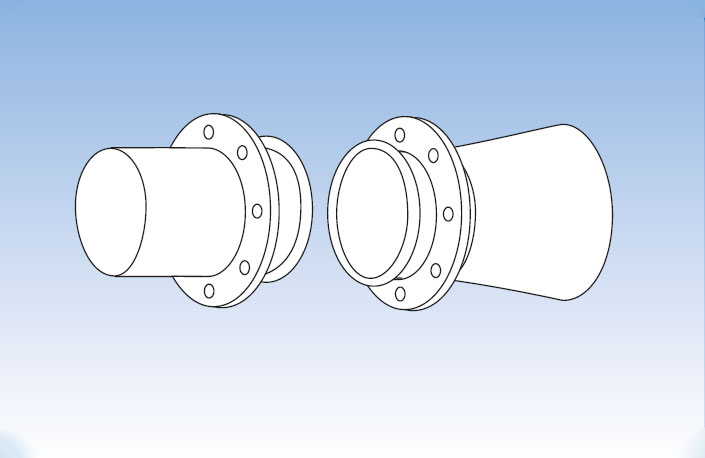

flanges [f.b.m.fl] are used for ø850 mm to ø1000 mm ducts.

2 and 3 mm duct system

The 2 and 3 mm system includes all components necessary for a complete and flexible extraction solution and can be used for particle transport, welding extraction etc.

- laser welded ducts

- plasma welded ducts

- pressed bends

- tight sliding dampers

- branch- and trouser pieces

- throttle valves

- diverters – pressed and welded

- adapters

The heavy duty sheet thickness means that this system is ideal for applications using high pressure or highly abrasive particles.

ø80 - ø400 mm ducts are laser welded. Other sizes are plasma welded. Bends, diverters, branch- and trouser pieces, shaped pieces etc are fully welded.

Ducts and shaped pieces are made of DC 01 or DOMEX 240 sheet metal with a thickness of 2 – 3 mm.

Pull rings [f.b] are used as standard joint assembly for rapid assembly and separation on ø80 mm to ø600 mm ducts, and loose flanges [m.fl] are used for ø650 mm to ø1000 mm ducts.

The duct system can be supplied with no surface treatment, powder coated primed (RAL7032), or powder coated with zinc primer and top coat paint.

Standard colour is RAL 5010, but other colours and hot dip/electro-galvanised finishes are available at an additional price.

Surface treatment

ProTechCon has installed a state-of-the art automatic 3-zone powder coating plant, which ensures high, uniform quality on all painted items.

Benefits of powder coating:

- High quality, impact and scratch-resistant surface

- High material usage – no evaporation

- Environment protection - no solvents

Primed duct systems fulfil corrosion class C2, cf. ISO 12944 and have received the following surface treatment:

1. Cleaning and iron phosphate finish at 50-55°C

2. Rinsed in water at 20-35°C

3. Rinsed with demineralised water at 15-30°C

4. Dried at 120-130°C

5. Robot-applied zinc epoxy-primer; layer thickness: 60-80 my

6. Primer hardening at 180-190°C.

Components with welded flanges are sandblasted to SA 2.5 before application of the above.

Duct systems can also be supplied painted (standard colour RAL 5010), with the before mentioned surface treatment but

with a layer thickness of 80-120 my. If a higher corrosion class is required, please specify when ordering. JKF can supply products which fulfil up to corrosion class C4, cf. ISO 12944.

Temperature range

Both duct systems can be used as standard at temperatures from -30°C to 80°C. Higher temperature tolerance available to order.

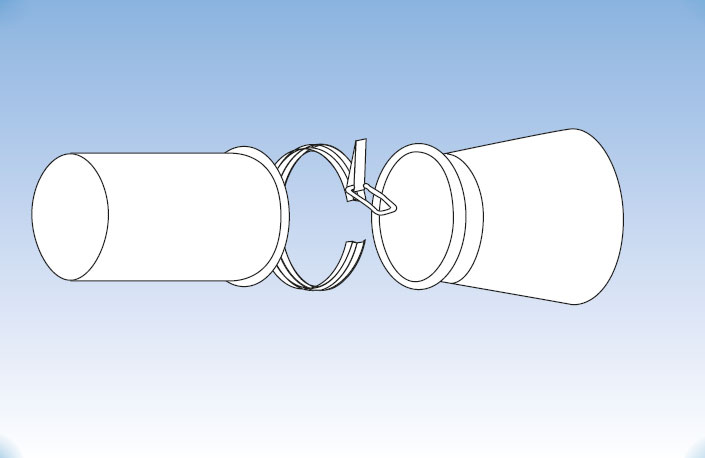

Tightness

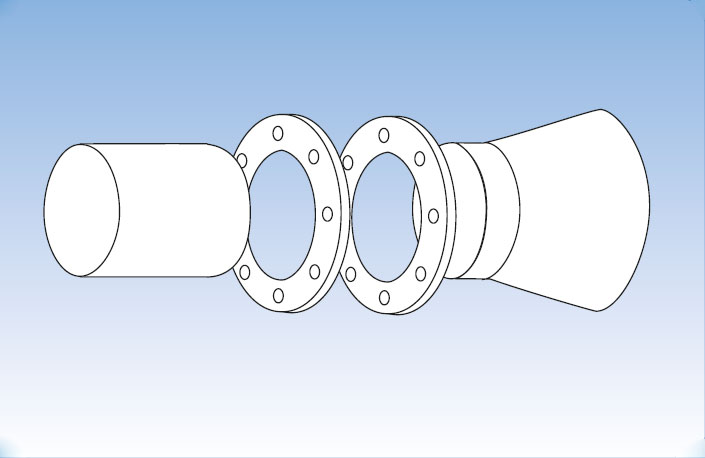

Leaks in a duct system mean loss of capacity and undesirable noise. The JKF duct systems are manufactured with minor tolerances, to ensure tight joints. Use of pull rings or rapid lock pull rings ensures that the duct section fulfills tightness class C,

the best tightness class within industrial extraction. Joint sealing compound or rubber flanges (EPDM) are recommended for flange assemblies to ensure tight joins. Correct assembly with sealing compound will result in assemblies which fulfil the requirements for tightness class C.

See appendix 1 page 69.

Quality assurance

JKF’s quality assurance system is certified according to DS/ISO9001 (DS/EN29001).

Assembly methodsgalvanised duct system

Assembly methods

The high, uniform quality of JKF’s duct systems along with efficient assembly and sealing ensures quick and easy assembly, with the ability to perform subsequent modifications.

The components for the galvanised duct system are made for a range of different assembly methods, which are also suitable for other systems.

Galvanised duct systems can be supplied to order for assembly with:

- pull rings [f.b]: ø80 – ø500 mm

- wide pull rings [f.bb]: ø150 – ø750 mm

- rapid lock pull rings with handle [f.lyn]: ø80– ø400 mm

- rapid lock pull rings with bolt [f.lyn]:ø450 – ø600 mm

- loose flanges [f.b.m.fl]: ø80 – ø1000 mm

- hoses [f.sl]: ø80 – ø400 mm

- smooth [gl]: ø80 – ø1000 mm

The assembly method depends on duct dimensions, strength, tightness, noise and installation requirements.

Tightness can be increased when using ø80 - ø300 mm pull rings by fitting a U-shaped rubber gasket ring (EPDM) on the f.b. edge. Rapid lock pull rings have a fixed liner (EPDM), which ensures an airtight join.

Assembly method must be stated when placing order. Assembly methods are stated under the illustrations.

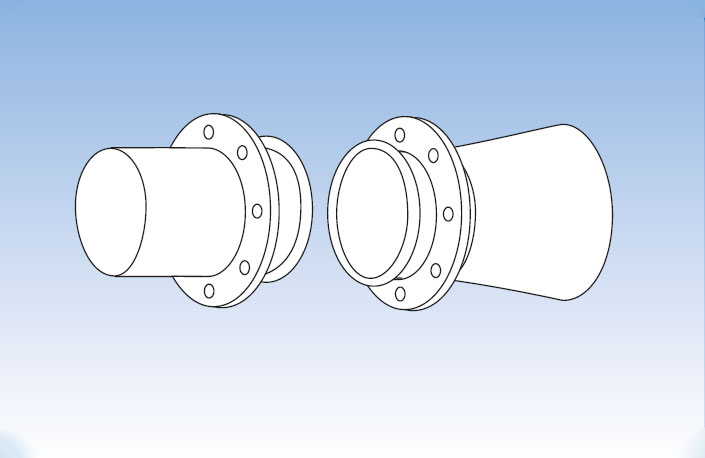

Assembly methods, 2 und 3mm duct systems

The high, uniform quality of JKF’s duct systems along with efficient assembly and sealing ensures quick and easy assembly, with the ability to perform subsequent modifications.

The components for 2 duct system are made for a range of different assembly methods, which are also suitable for other systems.

2 mm duct systems can be supplied to order for assembly with:

- 2 mm pull rings [f.b]: ø80 – ø600 mm

- rapid lock pull rings with handle [f.lyn]: ø80– ø400 mm

- rapid lock pull rings with bolt [f.lyn]: ø450 – ø600 mm

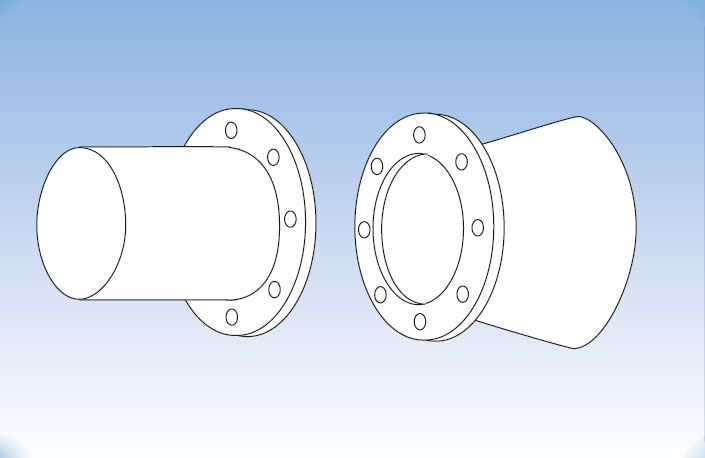

- loose flanges [f.b.m.fl]: ø80 – ø600 mm

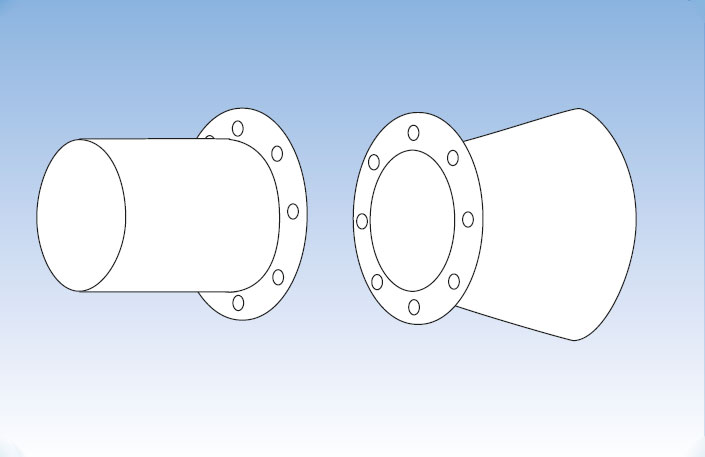

- welded flanges [m.fl]: ø80 – ø1000 mm

- direct flanges [d.fl]: ø300 – ø1000 mm

The assembly method depends on duct dimensions, strength, tightness, noise and installation requirements.

Tightness can be increased when using ø80 - ø300 mm pull rings by fitting a U-shaped rubber gasket ring (EPDM) on the f.b. edge. ø315 – ø600 mm pull rings can be supplied with integral seal at an additional price. Rapid lock pull rings have a fixed liner (EPDM), which ensures an airtight join.

Ducts with rapid lock pull rings, loose flanges or direct flanges assembly methods are fitted with a straight duct-shaped end piece with a length of min. 50 mm.

3 mm duct systems can be supplied to order for assembly with:

- rapid lock pull rings with-handle [f.lyn]: ø150 – ø400 mm

- rapid lock pull rings with bolt [f.lyn]: ø450 – ø600 mm

- welded flanges [m.fl.]: ø150 – ø1000 mm

Assembly method must be stated when placing order. Assembly methods are stated under the illustrations.

To max. ø600 mm diameter in 2.00 mm