Product description

The TMC magnetic circular pipes-separators,TMR rectangular-, TMA angular- and TMQ square magnetic separator are widely used to deferizeferrous paticle-polluted middlings, flours and powders etc.They represent the most suitable devices being not fed which can be assembled with ease.

Construction:

|

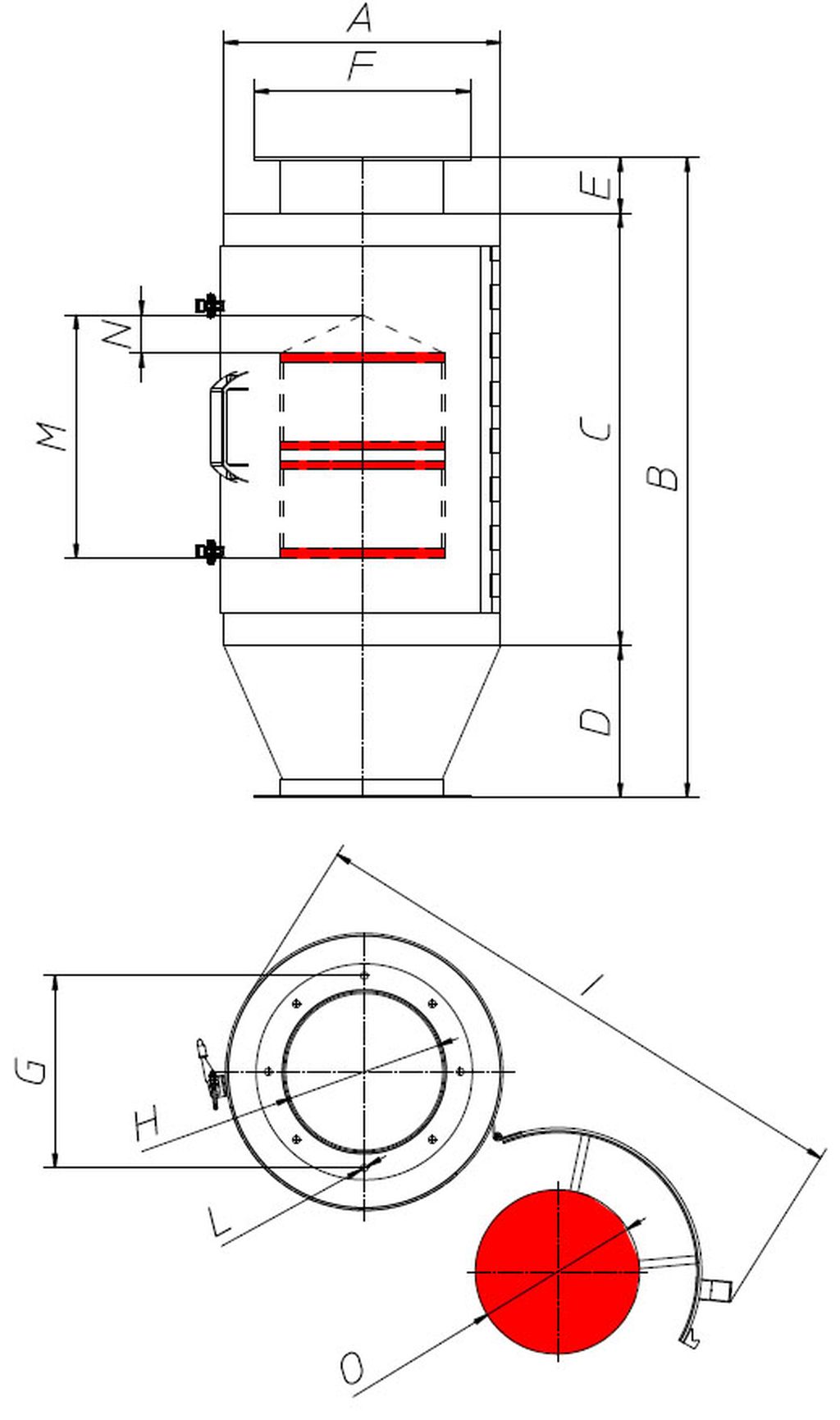

Magnet pipe is designed for separation from material with bad pouring properties (non free-flowing, bridging), where separator with magnetic grates could clog. Magnetic pipe separator can also be used for applications where bigger parts (wood chips) are conveyed in pipeline system. The inline magnetic separator inlet includes breaking cone which directs the falling or flowing material towards magnetic plates placed on inside the door walls of the inline magnet fitted with strong permanent magnets.

Magnetic separator can be simply and easily cleaned thanks to advanced cleaning system. The whole magnet plates can be opened which enables direct access to the interior of magnetic separator. Thanks to additional tilting stainless steel plates the cleaning of metallic parts is a matter of a few seconds. Inline magnet is standardly fitted with strong anisotropic ferrite magnets. For exacting applications can also be fitted with very strong neodymium NdFeB magnets. Consumer protection against eating dangerous metal pieces

Standard connection:

- Flange

- Jacob

Special connections on request

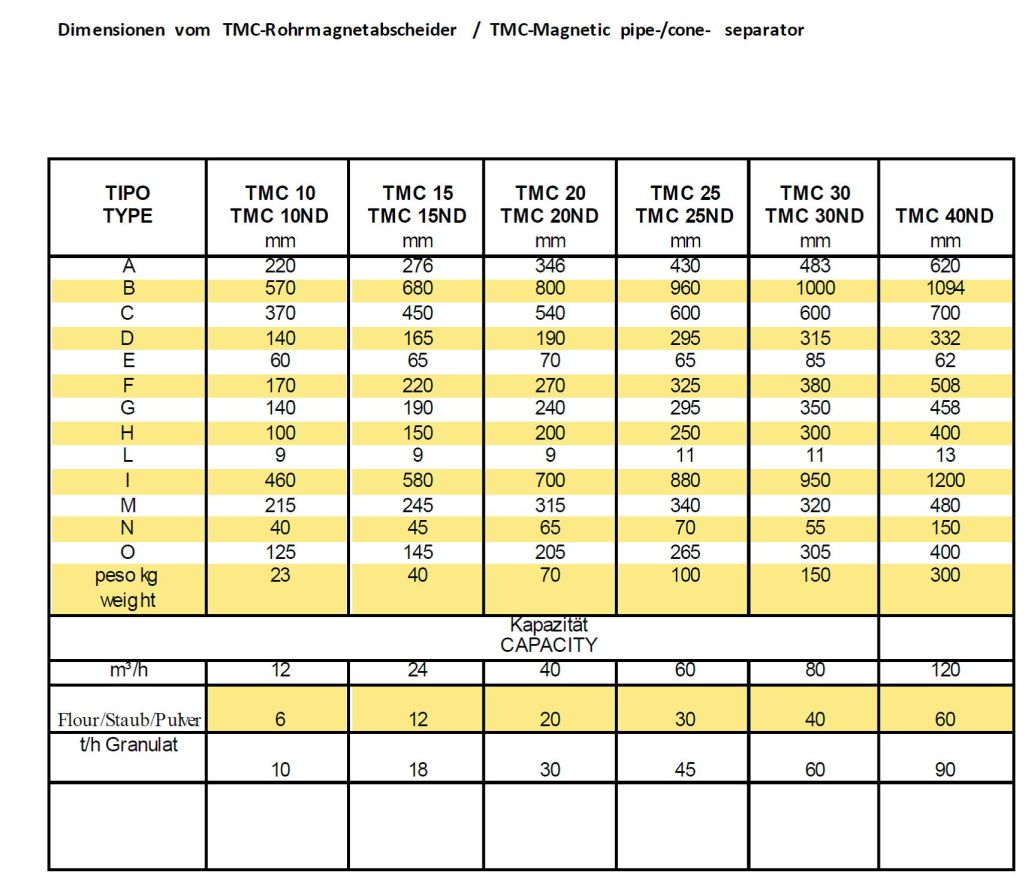

The size can be modified according to technical specifications or requirements of the customer. Production of specific non-standard diameters specified by the customer is also possible.