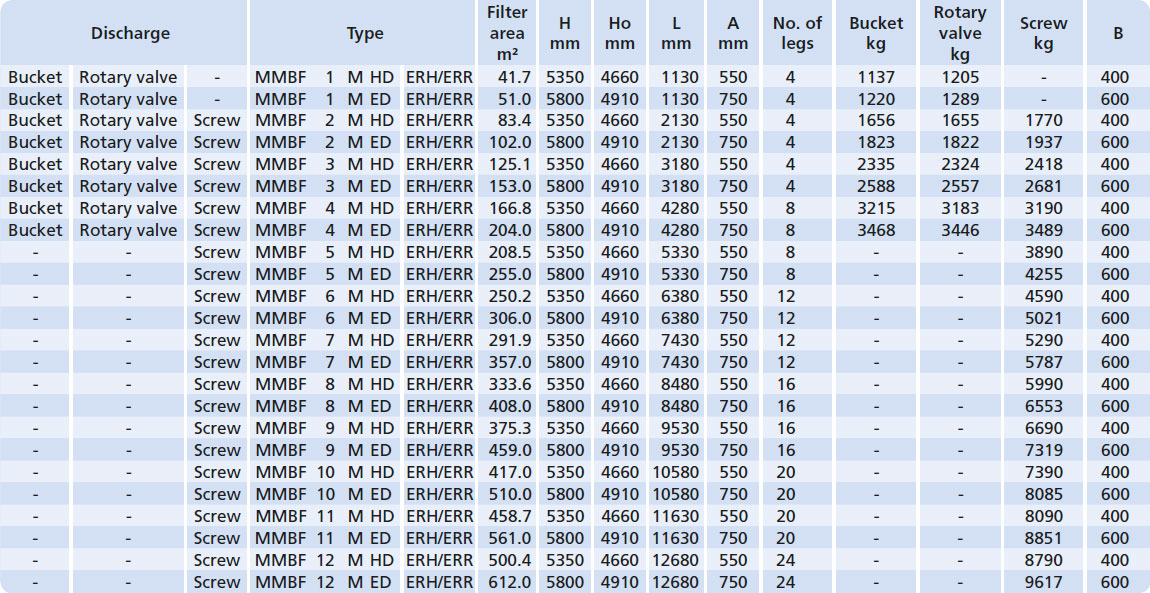

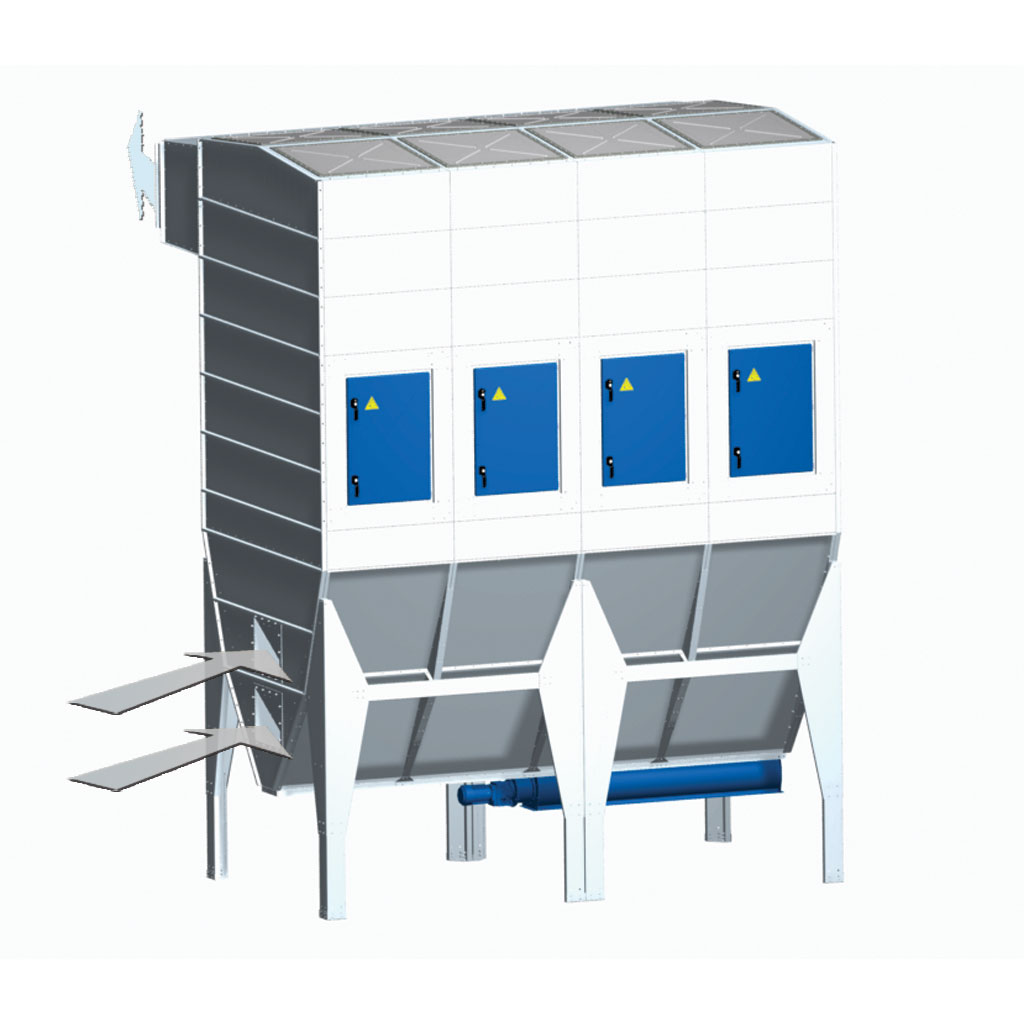

The MMBF filters (Multi Modular Bag Filter) are under- and over-pressure filters designed to run in constant operation. They are modular and can therefore be added to in line with growing capacity requirements and can be adapted to any task. More modules can subsequently be added, or they can be rebuilt to a different height or other material transport system to meet changed extraction needs. The MMBF filter is made of high tensile steel to ensure strength combined with low weight. The filter is self-supporting with adjustable legs, and can be erected outdoors or in.

More efficient operation

The number of filter bags per module is 30. This means large filter area and low riser speed in the filter for a given air volume. The perforated sheet is shaped to avoid chafing the filter bags. The bags are antistatic with a large diameter (220) and fitted with a snap ring fastener, reducing dust particle retention, enabling more efficient bag cleaning. The result is lower pressure loss and reduced risk of blockage. The partition wall between the modules makes continuous cleaning easy during operation.

Fast assembly

MMBF filters are factory-assembled as standard. A top and bottom part are delivered which can quickly be erected and assembled. The filters can also be supplied unassembled. The filter is multi-modular, and can be assembled using bolts in high tension steel with integrated washers, significantly reducing assembly time and the risk of over-tightening bolt assemblies.

Surface

Galvanised sheet, class Z 275 - zinc plating min. 275 g/m² double-sided.

Inlet

The MMBF filter is supplied with the supply air chamber in the conical bottom. Side inlet 300×400 mm is standard, but it can also be supplied with one and two end inlets 400×500 mm. The standard inlet is supplied with contra-flaps, which are open during normal filter operation, but close when the fan is switched off. The flaps prevent the air flow created by the regenerating fan returning into the pipe system.

Outlet

The MMBF filter has a built-in return air conduit. The outlet from the return air conduit is available with an ATEX-approved fire damper. Filter type H outlet is 450×950 mm and filter type E is 600×950 mm.

Cleaning system

The regenerating fan ensures easy, effective filter bag cleaning. One module at a time is regenerated, as there are partition walls between the modules.

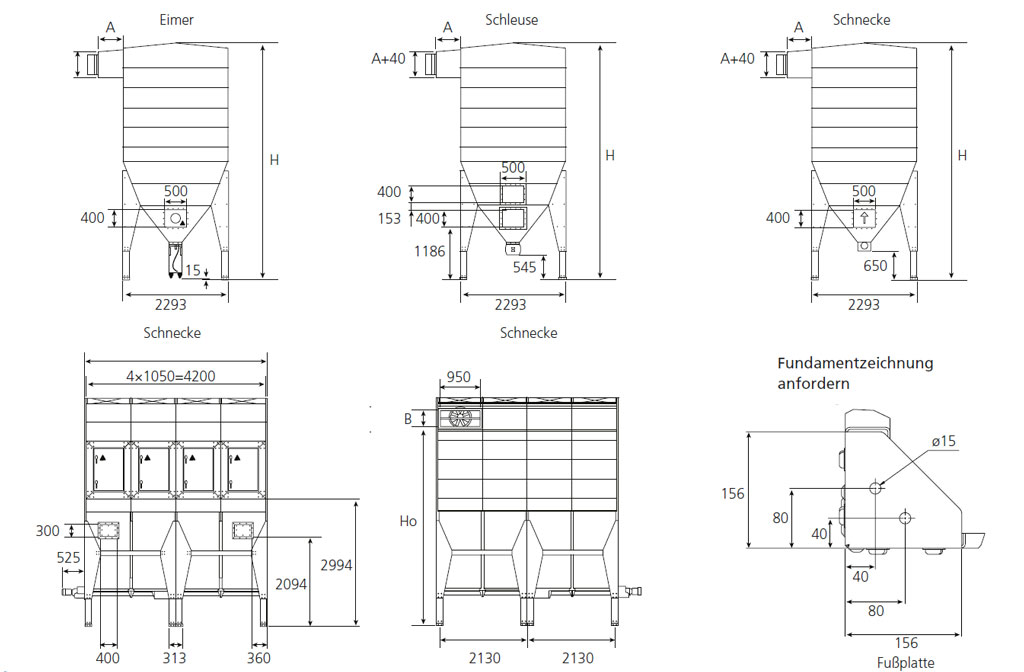

Discharge system

Screw, rotary valve or bucket discharge systems are available.

The MMBF screw is available in 2 to 12 modules. The screw is ø180 mm and made of AISI 304 and supplied as standard with 22 min-¹ or 43 min-¹.

The MMBF rotor filter is available with 1 to 4 modules and with JK-50S, JK-100S, JK-150S or JK-200S.

The MMBF bag emptying filter is available with 1 to 4 modules with a dust bucket under each. Buckets are supplied fully assembled direct

from JKF, fitted with inspection glass to give a good indication of fill status. Easily mounted, using a clamp with uniform key code.

The filter is fitted with a pressure-equalisation hose to prevent the bag being sucked up during startup at underpressure. Hose can be easily disconnected using a compressed air coupling.

ATEX

The MMBF filter is ATEX-approved and has approved explosion membranes. Choose between side venting in the cone (ERH) 600×600 KER or JKF’s specially developed VFV® explosion venting (ERR) 920×920 KER, which vents vertically through the filter top. The filters fulfil pressure shock-resistance according to VDI 2263. Venting according to VDI 3673.

Operating range

Pressure: +/- 5000 Pa

Filter area: 41.7-612 m²

Max. operating temperature: 70ºC

Min. operating temperature: -20ºC (available for: -40ºC)

Connection Motor

Regenerating fan

H filter ø450: 1.5 kW, 2900 min-¹, 3×400 V, 50 Hz, 3.2 A

E filter ø600: 1.5 kW, 1450 min-¹, 3×400 V, 50 Hz, 3.2 A

Screw:

0,55 kW, 22 min-¹, 3×400V, 50 Hz, 2,5 A

0,75 kW, 43 min-¹, 3×400V, 50 Hz, 3,2 A

Filter bags

30 filter bags per module

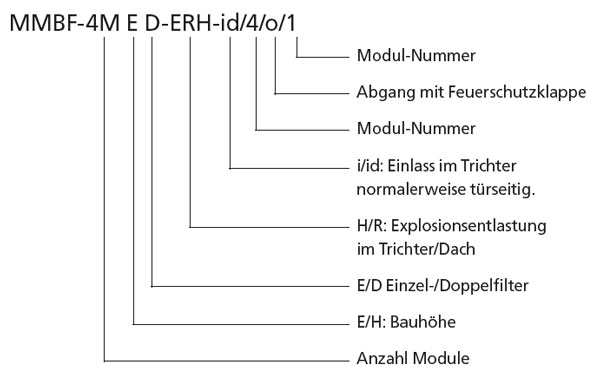

Type designations

Filters are type-designated using a combination of letters and numbers separated by hyphens and spaces. Designation MMBF-4M E D-ERHid/ 4/o/1 thus describes a MMBF filter with 4 modules, height, double filter, explosion relief venting in the cone, inlet in module 4, outlet with fire damper in module 1.